According to the needs of DONGFENG LIUZHOU MOTOR CO., LTD. product planning, 81 lines B1 of Liuzhou Liuxin Auto Stamping CO.,LTD passenger car welding line need to be demolished and rebuilt, and a simple B1 welding line should be built simultaneously to meet the production needs of sales demand. The time is imminent. Therefore, Liuxin Company is faced with an “impossible” challenge: it needs to dismantle the original B1 flexible line equipment and rebuild B1 simple line with the dismantled equipment within 45 days, and it needs to complete 2,200 sets of simple lines in the next 15 days at a low tempo!

For the construction and production of simple line, the period is short and urgent, the construction is complicated, the synchronous debugging, the product testing, the shortage of staff, the day shift and the night shift, and the rapid resumption of production … Faced with this year’s No.1 project in front of Liuxin Company, under the circumstance that there is no dedicated production line staff, and under the atmosphere of employees’ doubts that this is an impossible task, the Party branch gives full play to the advantages of employees’ ideological mobilization, and makes the company leaders “strive for every order” and “do it quickly”.

01

Round-the-clock construction, standard first careful debugging.

It is bound to make the simple line put into production is mass production.

From the dismantling of the original thread to the rebuilding of a simple thread, we pay close attention to the dismantling, packaging, migration and assembly of every machine, every part and every screw. The engineers “insist on this goal and don’t relax”, follow up every installation step in the whole process, and monitor the implementation of every process and standard. Closed-loop inspection and management of the problems in line debugging were conducted at daily construction meetings, and finally the first construction goal of “impossible task” was achieved with a 40-day construction period, 5 days ahead of the required construction period.

02

At the command, the commercial multiplication force quickly took place.

Training+improvement, production is mass production.

Simple Line is not equipped with special production personnel. In order to complete the output of 2,200 units in 15 days at a low tempo, four shifts are allocated from each production line of commercial vehicles and passenger cars. After the production of this line is completed, they will rush to Simple Line in turn for 24-hour production, so as to ensure the completion of the output! 4 shifts work continuously, which means that employees have to work night shifts. After each shift completes its inherent production tasks, each shift has to support simple line production, and the working hours are less than 10 o’clock every day. Four lines, four teams and groups, to fully realize the joint and coordination, to solve the production scheduling problem and employees’ ideological problems, the production plan of each line should be arranged very compactly and reasonably, and employees’ ideological mobilization and guidance should be done in the car.

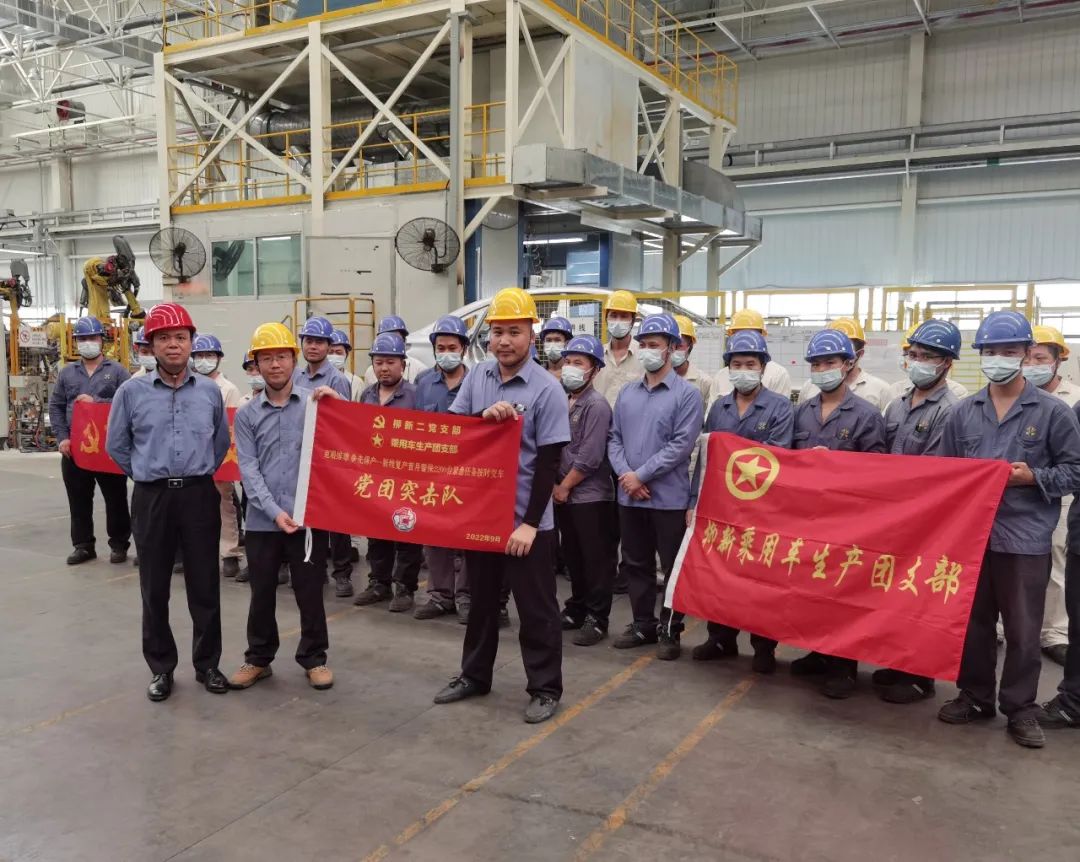

For this reason, various forms of production mobilization are carried out from the company leaders, the party work groups, the production departments and the production teams: all staff meetings, the company leadership mobilization meeting, the party branch secretary/workshop/team mobilization meeting, and the production commando of the party group, so as to talk to front-line employees in time and solve their worries. Dancers will go all out to enter production, strengthen their faith, and win this tough battle of resuming production!

In Liuxin B1 simple line, as long as you go to the site at any time, you can see that the employees are making every effort to complete the output of the day; You can see that the technical, equipment and quality engineers on the spot are concentrating on monitoring the normal operation of the line; You can see that department leaders are directing and coordinating to solve new problems on the spot …

From line construction to resumption of production, Liuxin Company successfully completed the production line construction in the face of the No.1 project entrusted by Dongfeng Liuzhou motor, under the organization and leadership of the Party branch, and in September, it took half a month to rotate around the clock to produce 2,200 new energy vehicles as an urgent order task! With my own actions, I responded to the ardent request of the leaders of Dongfeng Liuzhou motor that “every order should be fought”, “be quick and dry”, and strive to sprint the annual sales target of Dongfeng Liuzhou motor.

Web: https://www.forthingmotor.com/

Email:dflqali@dflzm.com lixuan@dflzm.com admin@dflzm-forthing.com

Phone: +867723281270 +8618577631613

Address: 286, Pingshan Avenue, Liuzhou, Guangxi, China

Post time: Dec-01-2022

SUV

SUV

Mpv

Mpv

Sedan

Sedan

EV

EV