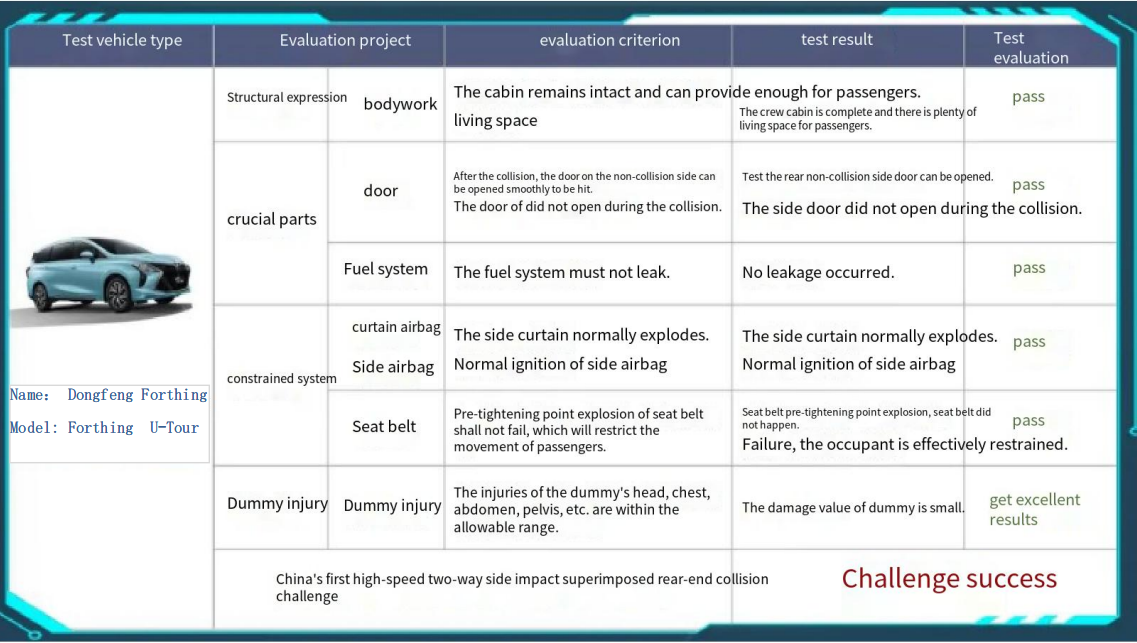

How does Dongfeng Forthing U-Tour fully protect the safety of all employees under the harsh conditions of double impact? This challenge will give you the answer!

Forthing U-Tour is the first public high-speed two-way side collision superimposed rear-end collision challenge in China!

Simulate daily driving.

High-speed side impact and high-speed rear-end collision.

Exceed conventional safety standards.

(60km/h ultra-high speed side impact +65km/h ultra-high speed rear-end collision)

60km/h side impact +65km/h rear-end collision test.

For the first time in China,

High-speed rear-end collision is superimposed after high-speed side collision.

The collision speed of trolley is increased by 20%, and the total kinetic energy is increased by 44%. Keep the vertical impact angle of 90 degrees while moving in both directions. Can the side structure of Forthing U-Tour car body stand the test?

ABCD pillar has no obvious deformation, and the door deformation degree is small.

The roof structure has no deformation or fracture.

Effectively ensure the living space of the occupants in the car.

In addition, after the collision,

The ECU can issue an instruction to unlock the door.

The door on the non-collision side can be opened normally, effectively ensuring the escape safety of the occupants in the car.

Keywords1: the introduction of vehicles

With EMA hypercube architecture,

The collision force is dispersed through the upper, middle and lower skeleton beam structural paths,

Ensure the safety performance of the whole vehicle.

Keywords 2: Design of energy-absorbing structure.

At the moment of collision, the energy-absorbing structure at the rear of the vehicle is deformed by collapsing,

Fully absorb the collision energy and alleviate the impact force generated by the collision.

The D-pillar has no obvious deformation or bending, which ensures the safety of the occupants in the car. The side tire hub is complete, there is no oil leakage on the ground, and the fuel system and chassis body structure are all in good condition.

Keywords 3: application of high-strength hot-formed steel

The threshold is made of high-strength steel, and the tensile strength of parts reaches 1180Mpa.

Thermoforming materials shall be applied in the overlapping core areas of side barriers, and the strength of vehicle body materials shall be matched to absorb collision energy. Column B is designed with thermoformed patch plate and internal partition plate, which can improve the deformation resistance of column B and control its stability.

Keywords 4: The side curtain of the airbag on the inside of the car is precisely exploded.

Side air curtain covering the third row+front middle row seat side airbag.

The response time of curtain deployment is within 6.4ms .

The pressure-keeping performance design of the air curtain on the inside of the car fully protects the occupant’s head from injury.

Keywords 5: seat belt restraint system matching

Pre-tightening and force-limiting seat belts in front and middle rows.

Eliminate slack gap of seat belt and effectively restrain passengers.

Guarding every breath of the crew is the eternal mission of Dongfeng Forthing.

This guardian challenge,

Forthing U-Tour “overfulfilled” the task.

Stay hurt in the experiment, and stay at ease in every drive. Dongfeng Forthing helps you have a worry-free journey.

Web: https://www.forthingmotor.com/

Email:dflqali@dflzm.com

Tel:0772-3281270

Phone: 18577631613

Address: 286, Pingshan Avenue, Liuzhou, Guangxi, China

Post time: Oct-27-2022

SUV

SUV

Mpv

Mpv

Sedan

Sedan

EV

EV