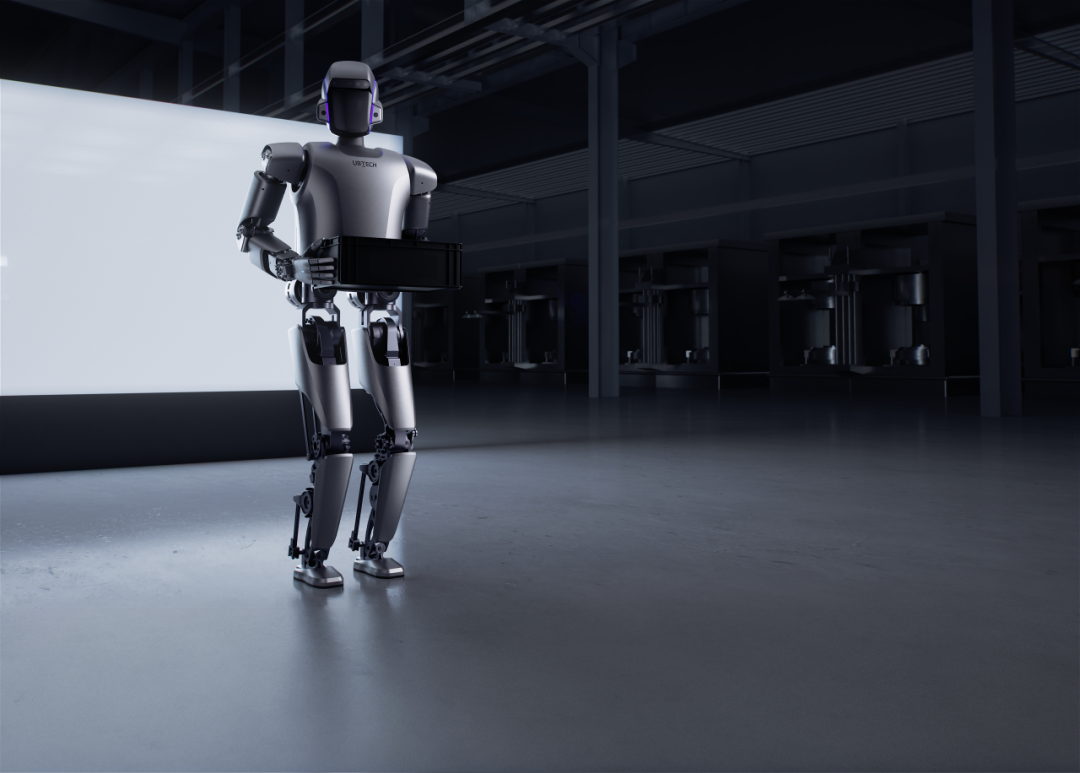

Recently, Dongfeng Liuzhou Motors (DFLZM) announced plans to deploy 20 Ubtech industrial humanoid robots, Walker S1, in its vehicle production plant within the first half of this year. This marks the world’s first batch application of humanoid robots in an automotive factory, significantly enhancing the facility’s intelligent and unmanned manufacturing capabilities.

As a key production base under Dongfeng Motor Corporation, DFLZM serves as a vital hub for independent R&D and exports to Southeast Asia. The company operates advanced automotive manufacturing facilities, including a new commercial and passenger vehicle production base in Liuzhou. It produces over 200 variants of heavy-, medium-, and light-duty commercial vehicles (under the “Chenglong” brand) and passenger cars (under the “Forthing” brand), with an annual production capacity of 75,000 commercial vehicles and 320,000 passenger vehicles. DFLZM’s products are exported to more than 80 countries and regions, including the Americas, Europe, the Middle East, and Southeast Asia.

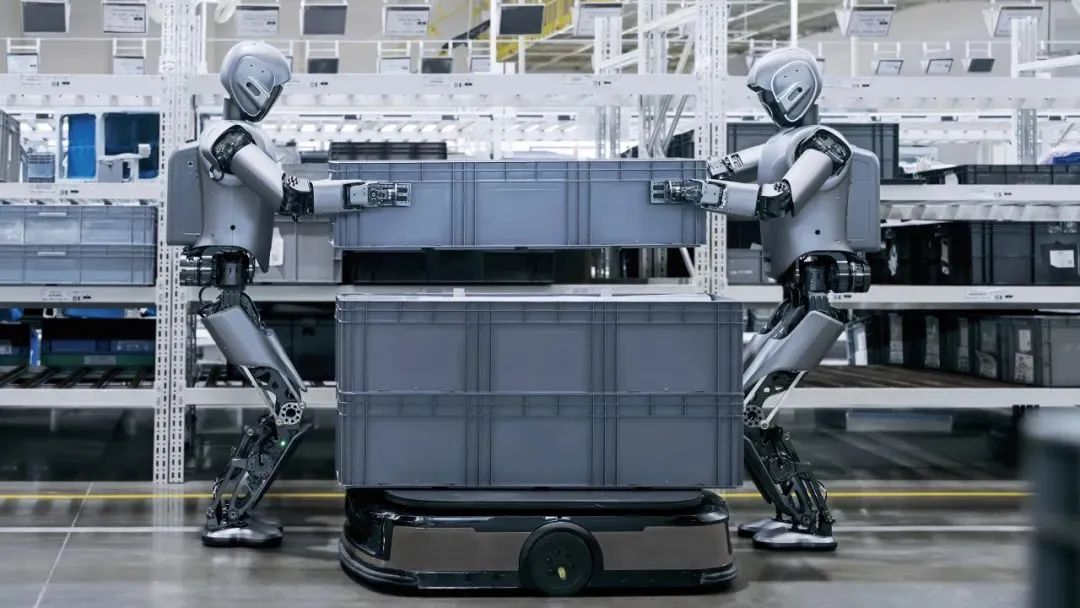

In May 2024, DFLZM signed a strategic agreement with Ubtech to jointly promote the application of Walker S-series humanoid robots in automotive manufacturing. After preliminary testing, the company will deploy 20 Walker S1 robots for tasks such as seatbelt inspection, door lock checks, headlight cover verification, body quality control, rear hatch inspection, interior assembly review, fluid refilling, front axle sub-assembly, parts sorting, emblem installation, software configuration, label printing, and material handling. This initiative aims to advance AI-driven automotive manufacturing and foster new-quality productive forces in Guangxi’s auto industry.

Ubtech’s Walker S-series has already completed its first-phase training in DFLZM’s factory, achieving breakthroughs in embodied AI for humanoid robots. Key advancements include improved joint stability, structural reliability, battery endurance, software robustness, navigation precision, and motion control, addressing critical challenges in industrial applications.

This year, Ubtech is advancing humanoid robots from single-unit autonomy to swarm intelligence. In March, dozens of Walker S1 units conducted the world’s first multi-robot, multi-scenario, multi-task collaborative training. Operating in complex environments—such as assembly lines, SPS instrument zones, quality inspection areas, and door assembly stations—they successfully executed synchronized sorting, material handling, and precision assembly.

The deepened collaboration between DFLZM and Ubtech will accelerate the application of swarm intelligence in humanoid robotics. The two parties are committed to long-term cooperation in developing scenario-based applications, building smart factories, optimizing supply chains, and deploying logistics robots.

As a new-quality productive force, humanoid robots are reshaping global tech competition in smart manufacturing. Ubtech will expand partnerships with automotive, 3C, and logistics industries to scale industrial applications and accelerate commercialization.

Post time: Apr-09-2025

SUV

SUV

Mpv

Mpv

Sedan

Sedan

EV

EV