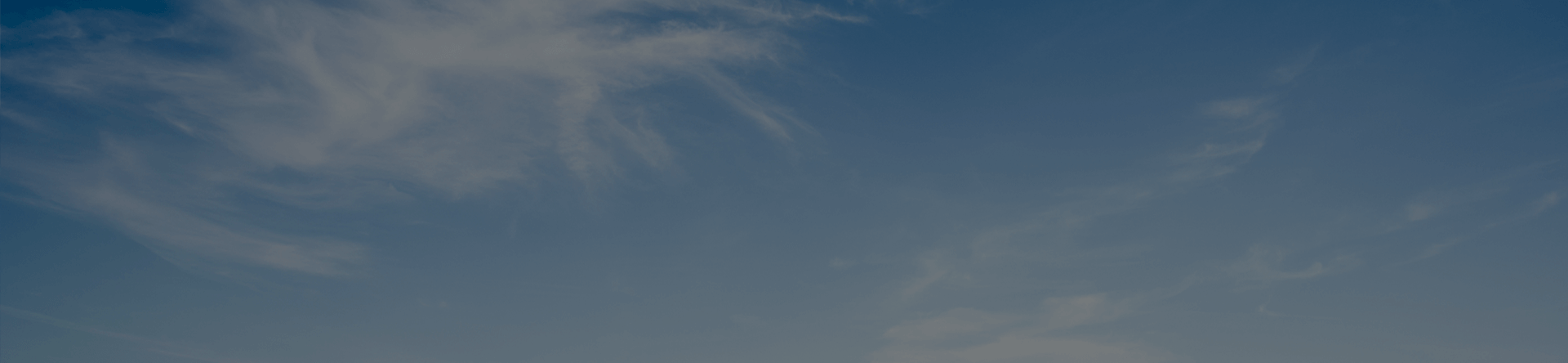

“China is so big, it is not enough to have a FAW alone, so the second automobile factory should be built.” At the end of 1952, after all the construction plans of the first automobile factory were determined, Chairman Mao Zedong gave the instructions to build the second automobile factory. The following year, the first Ministry of Machinery Industry started the preparatory work of No.2 Automobile Company, and set up the preparatory office of No.2 Automobile Factory in Wuhan.

After listening to the opinions of Soviet experts, the site was selected in Wuchang area and reported to the State Construction Committee and the First Machinery Industry Department for approval. However, after the scheme was reported to No.1 Machinery Department, it caused a lot of controversy. The State Construction Committee, No.1 Machinery Department and Automobile Bureau all thought that it was very advantageous to build No.2 Automobile in Wuhan from the perspective of economic construction. However, Wuhan is only about 800 kilometers away from the coastline and located in the plain where factories are concentrated, so it is easy to be attacked by the enemy after the outbreak of war. After fully examining the big environment of our country at that time, No.1 Machinery Department finally rejected the proposal to build a factory in Wuchang.

Although the first proposal was rejected, the plan to build the second automobile factory did not run aground. In July, 1955, after some argumentation, the senior management decided to move the site of No.2 Automobile from Wuchang to Baohechang in the eastern suburb of Chengdu, Sichuan. This time, the senior leaders were very determined to build No.2 Automobile, and even built a dormitory area of nearly 20,000 square meters in the suburb of Chengdu very early.

In the end, this plan didn’t come true as scheduled. In view of the domestic dispute over the size of the site of No.2 Automobile, and the excessive infrastructure projects in China during the First Five-Year Plan period, the plan to build a factory of No.2 Automobile was temporarily suspended in early 1957 under the influence of the “anti-aggressive” trend. At this time, more than a thousand automobile talents who had already rushed to Sichuan were also transferred to the No.1 Automobile Department, No.1 Automobile Factory and other enterprises to work.

Shortly after the second automobile project was temporarily won, China once again ushered in a good opportunity to support the launch of the second automobile. At that time, China’s volunteers who entered the DPRK returned to China in large numbers, and the government was faced with the difficult problem of how to resettle troops. Chairman Mao proposed to transfer a division from the returned volunteers and rush to Jiangnan to prepare for the second automobile factory.

As soon as this was said, the upsurge of building the second automobile factory was set off again. This time, Li Fuchun, then deputy prime minister, pointed out: “There is no big factory in Hunan in the Yangtze River valley, so the second automobile factory will be built in Hunan!” At the end of 1958, after receiving the instructions of the Deputy Prime Minister, the Automobile Bureau of the First Machinery Department organized forces to carry out site selection work in Hunan.

In February, 1960, after the preliminary site selection, the Automobile Bureau submitted a report on some issues concerning the construction of the No.2 Automobile Factory to the No.1 Automobile Factory. In April of the same year, the No.1 Automobile Factory approved the plan and set up a mechanic training class of 800 people. Seeing that the Second Automobile Factory will break ground smoothly with the support of all parties, the “three-year difficult period” since 1959 once again pressed the pause button for the start-up of the Second Automobile Project. As the country was in an extremely difficult economic period at that time, the start-up capital of the Second Automobile Project was delayed, and this ill-fated automobile factory project had to dismount again.

Being forced to dismount twice really makes many people feel sorry and disappointed, but the central government has never given up the idea of building the second automobile factory. In 1964, Mao Zedong proposed to pay close attention to the third-line construction, and put forward the idea of building the second automobile factory for the third time. The No.1 engine factory responded positively, and the site selection of No.2 automobile factory was carried out again.

After a series of investigations, several preparatory groups decided to choose the site near Chenxi, Luxi and Songxi in western Hunan, so it spanned three streams, so it was called “Sanxi Scheme”. Subsequently, the preparatory group reported the Sanxi scheme to the leaders, and it was approved. The selection of the site of No.2 Steam Turbine took a big step forward.

Just as the site selection was in full swing, the central government sent the highest instructions, and put forward the six-character policy of “relying on the mountain, dispersing and hiding”, requiring the site to be as close to the mountains as possible, and the key equipment to enter the hole. In fact, from these instructions, it is not difficult to see that at that time, our government focused on the war factor in the site selection of the No.2 Automobile Company. From this, we can also know that the world environment of New China, which has just been established for more than ten years, is not peaceful.

After that, Chen Zutao, an automobile expert who was then the director and chief engineer of Changchun Automobile Factory, rushed to the site selection. After a lot of investigation and measurement work, dozens of members of the preparatory group basically determined the site selection scheme in October 1964 and returned in batches. However, just after the site selection scheme was submitted to the superior, the site selection process of No.2 Automobile Company changed unexpectedly.

According to rough statistics, during the 15-month site selection from October, 1964 to January, 1966, dozens of people participated in the site selection of the No.2 Automobile Factory, and surveyed 57 cities and counties on the spot, driving about 42,000 kilometers by car, and recording more than 12,000 data. Many members of the preparatory group even went home for a rest once during the 10-month inspection. Through a systematic and complete evaluation of the actual situation in many areas, it was finally determined that the Shiyan-Jiangjun River area was the most suitable for building factories, and the site selection scheme was submitted in early 1966. It has to be said that the spirit of the older generation of autobots in China who are hard-working and not afraid of difficulties is indeed worth learning from the current domestic automakers.

However, at this stage, the site selection of No.2 Automobile Company was still unfinished. Since then, the central government has dispatched many technicians from all over the world to supplement and optimize the site selection of No.2 Automobile Factory. It was not until October 1966 that the plan of No.2 Automobile Company to build a factory in Shiyan was basically finalized.

But it didn’t take long for the Second Automobile Company to get into trouble again. In 1966, the Cultural Revolution broke out in China. At that time, many Red Guards organized to write to Li Fuchun, Vice Premier of the State Council, many times, arguing that there were many fundamental problems in the establishment of the Second Automobile Company in Shiyan. As a result, the plan to build the second automobile factory was postponed again.

In April, 1967 and July, 1968, the main leaders of No.1 Engine Factory went to the site selection of No.2 Steam Turbine and held two site adjustment meetings. Finally, after discussion at the meeting, it was considered that the decision to build No.2 Steam Turbine in Shiyan was correct, but only the specific details needed to be adjusted. Therefore, No.1 Engine Factory formulated the principle of “basic immobility and appropriate adjustment”, and made partial fine-tuning to the No.2 Steam Turbine site. After 16 years of “two times and three times”

Since the establishment of the factory in Shiyan in 1965, No.2 Automobile Company has started the development and production of its models in a simple temporary factory. At the beginning of 1965, the First Machinery Department held a technical policy and planning meeting of automobile industry in Changchun, and decided to place Changchun Automobile Research Institute under the leadership of No.2 Automobile Company. At the same time, it imported the models of Wanguo and Dodge brands for reference, and developed the first military off-road vehicle of No.2 Automobile Company with reference to the Jiefang truck produced at that time.

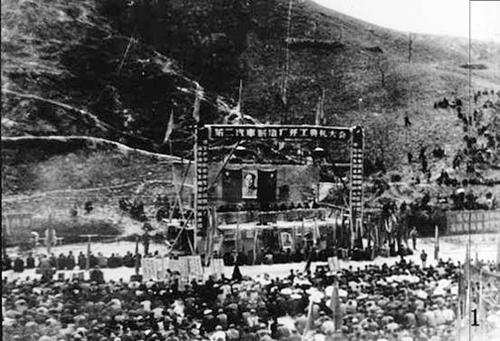

On April 1st, 1967, the No.2 Automobile Company, which had not officially started construction, held a symbolic groundbreaking ceremony in Lugouzi, Shiyan, Hubei Province. As the Cultural Revolution had already arrived at that time, the commander of Yunyang Military Region led troops to station in the preparatory office to prevent accidents. It was not until two years after this groundbreaking ceremony that the No.2 Automobile Company actually started construction.

As a result of the instruction of the central government that “the army should be given priority to, and the army should be put before the people”, the Second Automobile Company decided to produce a 2.0-ton military off-road vehicle and a 3.5-ton truck in 1967. After the model has been determined, the No.2 Automobile Company can’t come up with a decent production R&D team. Faced with the extreme shortage of talents, the CPC Central Committee called on other domestic automobile manufacturers to deploy core talents to help No.2 Automobile Company tackle key production problems.

In 1969, after several twists and turns, the No.2 Automobile Factory began to build on a large scale, and 100,000 construction troops successively gathered in Shiyan from all directions of the motherland. According to statistics, by the end of 1969, there were 1,273 cadres, engineers and technical workers who volunteered to participate in and support the construction of No.2 Automobile Factory, including Zhi Deyu, Meng Shaonong and a large number of top domestic automobile technical experts. These people almost represented the highest level of China’s automobile industry at that time, and their team became the backbone of the Second Automobile Company.

It was not until 1969 that the Second Automobile Company officially kicked off the large-scale production and construction. The first batch of research and development models were 2.0-ton military off-road vehicles, code-named 20Y. At the beginning, the purpose of producing this vehicle was to drag artillery. After the prototype was produced, the Second Automobile Company developed a number of derivative models based on this model. However, due to the upgrade of combat readiness and the increase of traction weight, the army demanded that the tonnage of this car be raised to 2.5 tons. This model named 20Y was not put into mass production, and the Second Automobile Company also turned to develop this new car named 25Y.

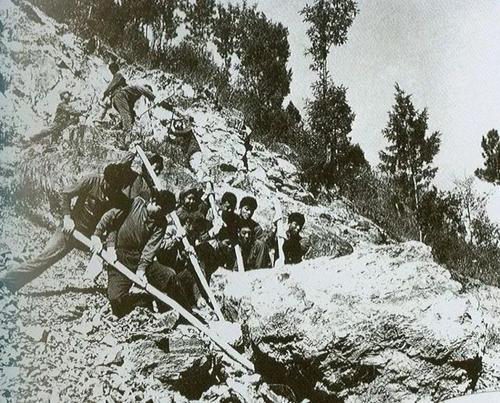

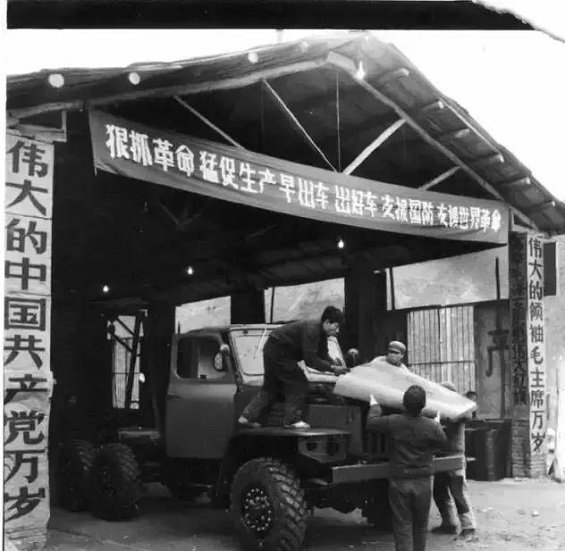

After the vehicle model was determined and the production team was complete, new problems were once again faced by No.2 Automobile Company. At that time, China’s industrial base was very weak, and the production materials of No.2 Automobile Company in the mountains were extremely scarce. At that time, let alone large-scale production equipment, even the factory buildings were temporary reed mat sheds, with linoleum as the ceiling, reed mats as partitions and doors, and a “factory building” was thus built. This kind of reed mat shed could not only withstand the hot summer and cold, but even shelter from the wind and rain.

What’s more, the equipment used by the workers of No.2 Automobile Company at that time was limited to primary tools such as hammers and hammers. Relying on the technical support of the No.1 Automobile Factory and referring to the technical parameters of Jiefang Truck, the Second Automobile Company put together a 2.5-ton 25Y military off-road vehicle in a few months. At this time, the shape of the vehicle has changed a lot compared with before.

Since then, the 2.5-ton military off-road vehicle produced by the Second Automobile Company has been officially named EQ240. On October 1st, 1970, No.2 Automobile Company sent the first batch of EQ240 models pieced together to Wuhan to participate in the commemoration parade of the 21st anniversary of the founding of the People’s Republic of China. At this time, the people of No.2 Automobile Company who produced this car were worried about the stability of this patchwork model. The factory even sent more than 200 workers of various trades to squat behind the rostrum at the parade site with repair tools for several hours, so as to repair the EQ240 with problems at any time. It was not until EQ240 successfully passed the rostrum that the hanging heart of the Second Automobile Company was put down.

These ridiculous stories don’t look glorious today, but for people at that time, they are a true portrayal of the hard work of the Second Automobile Factory in its early days. On June 10, 1971, the first automobile assembly line of No.2 Automobile Company was completed, and the second automobile company with a complete assembly line seemed to welcome spring. On July 1, the assembly line was debugged and successfully tested. Since then, the second automobile company has ended the history of hand-made automobiles in Luxipeng.

Since then, in order to change the image of EQ240 in people’s minds, the technical team led by Chen Zutao has started the transformation of EQ240 after the completion of the assembly line. After several improvements in the conference of tackling key problems, commissioning and engineering quality repair, the Second Automobile Company has solved 104 key quality problems of EQ240 in more than one year, involving more than 900 modified parts.

From 1967 to 1975, after eight years of research and development, production and improvement, EQ240, the first military off-road vehicle of the Second Automobile Manufacturing Plant, was finally finalized and put into mass production. The military off-road vehicle named EQ240 refers to the liberation truck at that time, and the vertical front grille matches with the iconic truck design of that era, which makes this car look quite tough.

At the same time, No.2 Automobile Company declared to the State Council that the brand name of its products would be “Dongfeng”, which was approved by the State Council. Since then, the second automobile and Dongfeng have become the words that are bound together.

At the end of 1970s, China and the United States gradually normalized diplomatic relations, but the former Soviet Union, a big brother, was eyeing China’s border. With the support of the former Soviet Union, Vietnam frequently provoked China-Vietnam border, constantly killing and injuring our border people and border guards, and invading China’s territory. Under such circumstances, China launched a self-defense counterattack against Vietnam at the end of 1978. At this time, EQ240, which had just been formed, went with it and went to the front line for the most rigorous test.

From the first EQ240 built in Luxipeng to the successful completion of the counterattack against Vietnam, the second automobile factory also achieved a leap in production capacity. In 1978, the assembly line of No.2 Automobile Company had formed a production capacity of 5,000 units per year. However, the production capacity went up, but the profit of No.2 Automobile Company fell. The main reason for this situation is that No.2 Automobile Company has always produced military off-road vehicles and trucks serving the army. With the end of the war, these guys with large volume and high cost have no place to use, and No.2 Automobile Company has fallen into the dilemma of loss.

In fact, before the counterattack against Vietnam started, the domestic automobile industry, including No.2 Automobile Company, foresaw this situation. Therefore, as early as 1977, FAW transferred the technology of its 5-ton truck CA10 to No.2 Automobile Company for free, so that No.2 Automobile Company could develop a civil truck to avoid this situation as much as possible.

At that time, FAW built a truck named CA140, which was originally intended to be the replacement of CA10. At this time, FAW generously transferred this truck to No.2 Automobile Company for their research and production. Theoretically, CA140 is the predecessor of EQ140.

Not only the technology, but also the backbone of CA10 model developed by FAW, helping the Second Automobile Company to develop this civilian truck. Because these technicians have relatively rich experience, the research and development process of this truck is very smooth. At that time, many 5-ton truck samples in the world were analyzed and compared. After five rounds of rigorous tests, the R&D team solved nearly 100 problems, large and small. This civilian truck named EQ140 was quickly put into mass production under the active promotion of the top management.

The significance of this EQ140 civil truck for the Second Automobile Company is far more than that. In 1978, the production task assigned by the state to No.2 Automobile Company was to produce 2,000 civilian vehicles, with a bicycle cost of 27,000 yuan. There was no target for military vehicles, and the state planned to lose 32 million yuan, compared with the previous target of 50 million yuan. At that time, No.2 Automobile Company was still the biggest loss-making household in Hubei Province. To turn losses into profits, cost reduction was the key, and 5,000 civilian vehicles had to be produced, which reduced the cost from 27,000 yuan to 23,000 yuan. At that time, the Second Automobile Company put forward the slogan of “guaranteeing quality, striving for overproduction and twisting losses”. Around this decision, it is also proposed to “fight for the improvement of product quality”, “fight for the construction of 5-ton truck production capacity”, “fight for the loss-making hat” and “fight for the annual production of 5,000 5-ton trucks”.

With the support of Hubei’s power, in 1978, No.2 Automobile Company officially launched a tough battle to turn losses into profits with this car. In April 1978 alone, it produced 420 EQ140 models, producing 5,120 vehicles in the whole year, with an over-production of 3,120 vehicles in the whole year. Instead of turning the planned losses into reality, it turned over 1.31 million yuan to the state and turned losses into profits in an all-round way. Created a miracle at that time.

In July, 1980, when Deng Xiaoping inspected the Second Automobile Company, he said, “It’s good that you pay attention to military vehicles, but in the long run, fundamentally speaking, we still need to develop civilian products.” This sentence is not only an affirmation of the previous development direction of No.2 Automobile Company, but also a clarification of the fundamental policy of “transferring from military to civilian”. Since then, No.2 Automobile Company has expanded its investment in civilian vehicles and increased the production capacity of civilian vehicles to 90% of the total production capacity.

In the same year, the national economy entered an adjustment period, and the No.2 Automobile Company was listed as a “suspended or delayed” project by the State Council. Faced with the grim situation, the decision-makers of No.2 Automobile Company put forward a report of “living within our means, raising funds by ourselves, and continuing to build No.2 Automobile Company” to the state, which was approved. “The’ weaning’ of the country and the bold development of enterprises are 10 times and 100 times stronger than the step-by-step construction under the planned economic system, which has really liberated the productive forces, promoted the rapid development of the Second Automobile Company and made substantial contributions to the country’s economic development.” Huang Zhengxia, then director of the Second Automobile Company, wrote in his memoirs.

Although the No.2 Automobile Company continued to innovate on the basis of EQ240 and EQ140 models, the product structure of China’s domestic automobile industry was seriously out of balance at that time. “Lack of weight and light weight, almost a blank car” was an urgent problem for major automobile manufacturers at that time. Therefore, in the product development plan of 1981-1985, No.2 Automobile Company once again put forward the plan of developing flathead diesel truck, in order to fill the gap of “lack of weight” in China.

In order to shorten the period of product improvement, and also to cater to the domestic reform and opening-up environment at that time, the Second Automobile Company decided to learn from foreign advanced technical experience to complete the research and development of this flat-headed heavy truck. After several years of research and improvement, a brand-new 8-ton flat-head diesel car slowly rolled off the assembly line in 1990. This car is called EQ153. At that time, people spoke highly of this EQ153 with beautiful appearance and excellent performance, and “driving eight flat firewood and making money roll in” was a portrayal of the true aspirations of the majority of car owners at that time.

In addition, the capacity of No.2 Automobile Co., Ltd. also developed rapidly during this period. In May 1985, the 300,000 Dongfeng vehicles rolled off the assembly line. At that time, the cars produced by No.2 Automobile Co., Ltd. accounted for one-eighth of the national car ownership. Just two years later, No.2 Automobile Co., Ltd. ushered in the 500,000 vehicles rolled off the assembly line and successfully achieved the annual output of 100,000 vehicles, ranking among the enterprises with the largest annual output of medium-sized trucks in the world.

Before the Second Automobile Company was officially renamed “Dongfeng Motor Company”, the leadership at that time proposed that truck building was only “elementary school level” and car building was “university level”. If you want to be stronger and bigger, you must build a small car. At that time, in the domestic automobile market, Shanghai Volkswagen was already quite large, and the Second Automobile Company took advantage of this opportunity and put forward a set of joint venture car development plan.

In 1986, then No.2 Automobile Company officially submitted to the State Council the Report on the Preliminary Work of Developing Ordinary Cars in No.2 Automobile Factory. With the strong support of relevant parties, the leaders of the State Economic Commission, Planning Commission, Machinery Commission and other departments attended the Beidaihe Conference in 1987. The conference mainly discussed the development of cars by the Second Automobile Company. Just after the meeting, the central government formally agreed to the strategic policy of “joint development, joint venture to set up factories, export orientation and import substitution” put forward by the Second Automobile Company.

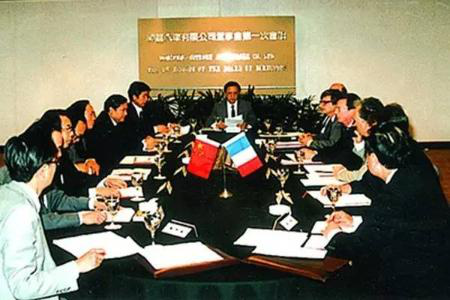

After the joint venture plan was approved by the central government, No.2 Automobile Company immediately carried out extensive international exchanges and began to seek partners. During the period of 1987-1989, the then Second Automobile Company entered into 78 cooperation negotiations with 14 foreign automobile companies, and sent 11 delegations to visit, and received 48 delegations to visit and exchange in the factory. Finally, Citroen Automobile Company of France was selected for cooperation.

In the 21st century, Dongfeng ushered in the climax of joint venture layout construction. In 2002, Dongfeng Motor Company signed a joint venture contract with PSA Group of France to expand cooperation, and the main content of this joint venture is to introduce Peugeot brand into China in an all-round way. After the joint venture, the company name is Dongfeng Peugeot. In 2003, Dongfeng Motor Company experienced a joint venture reorganization again. Dongfeng Motor Company finally reached an agreement with Nissan Motor Company to set up Dongfeng Motor Co., Ltd. in the form of 50% investment. Subsequently, Dongfeng Motor Company established contact with Honda Motor Company. After consultation, the two parties each invested 50% to set up Dongfeng Honda Motor Company. In just two years, Dongfeng Motor Company signed joint venture agreements with three automobile companies in France and Japan.

So far, Dongfeng Motor Company has formed a series of products based on medium trucks, heavy trucks and cars. Throughout the 50-year development history of Dongfeng brand, opportunities and challenges have always accompanied Dongfeng people. From the difficulty of building factories at the beginning to the difficulty of independent innovation now, Dongfeng people have gone through a thorny road with the courage to change and perseverance.

Web: https://www.forthingmotor.com/

Email:dflqali@dflzm.com lixuan@dflzm.com admin@dflzm-forthing.com

Phone: +867723281270 +8618577631613

Address: 286, Pingshan Avenue, Liuzhou, Guangxi, China

Post time: Mar-30-2021

SUV

SUV

Mpv

Mpv

Sedan

Sedan

EV

EV