DFLZ KD Project Planning and Implementation

DFLZ provides one-stop service for KD design, equipment procurement, installation and commissioning, trial production, and SOP guidance. We can design and build different level of KD factories based on customer needs.

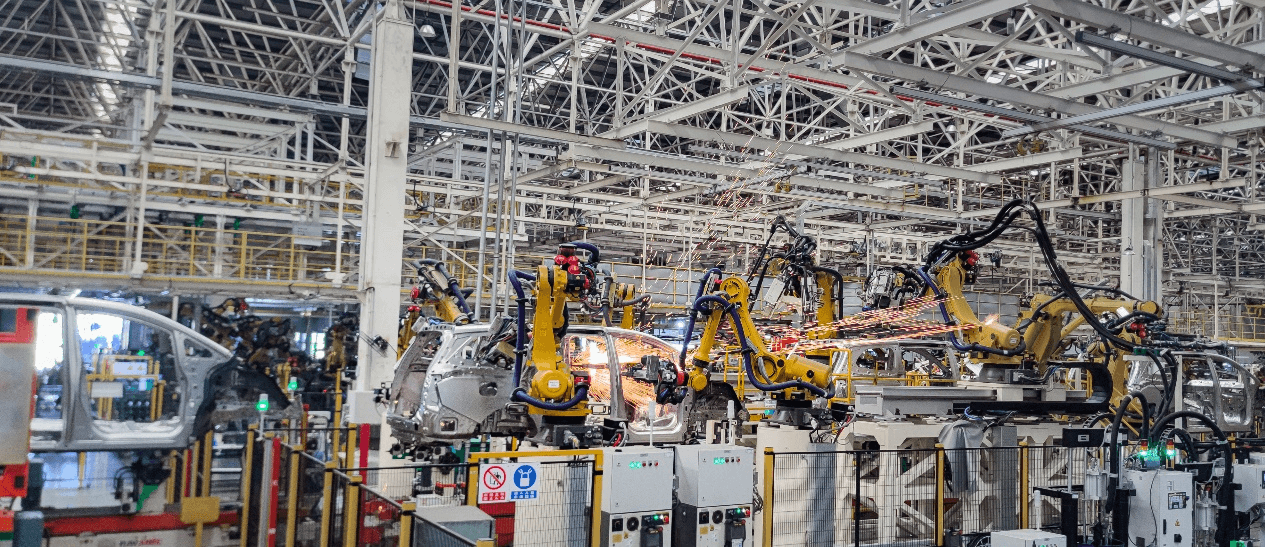

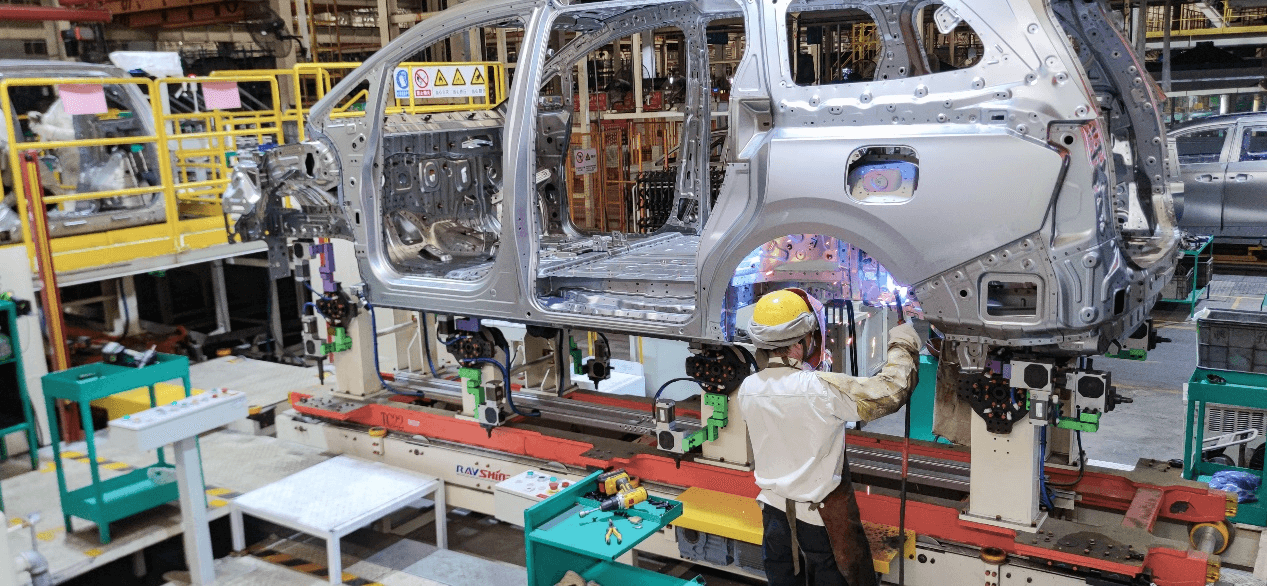

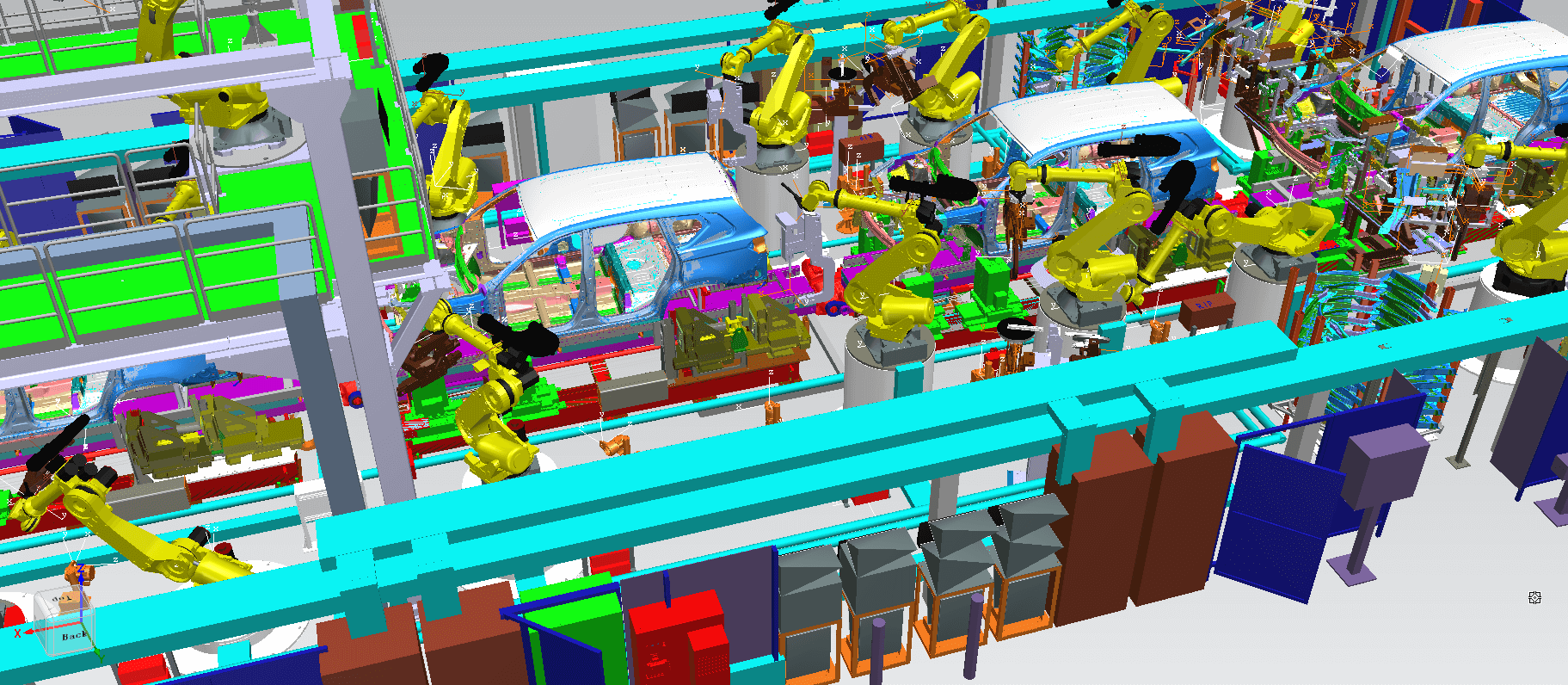

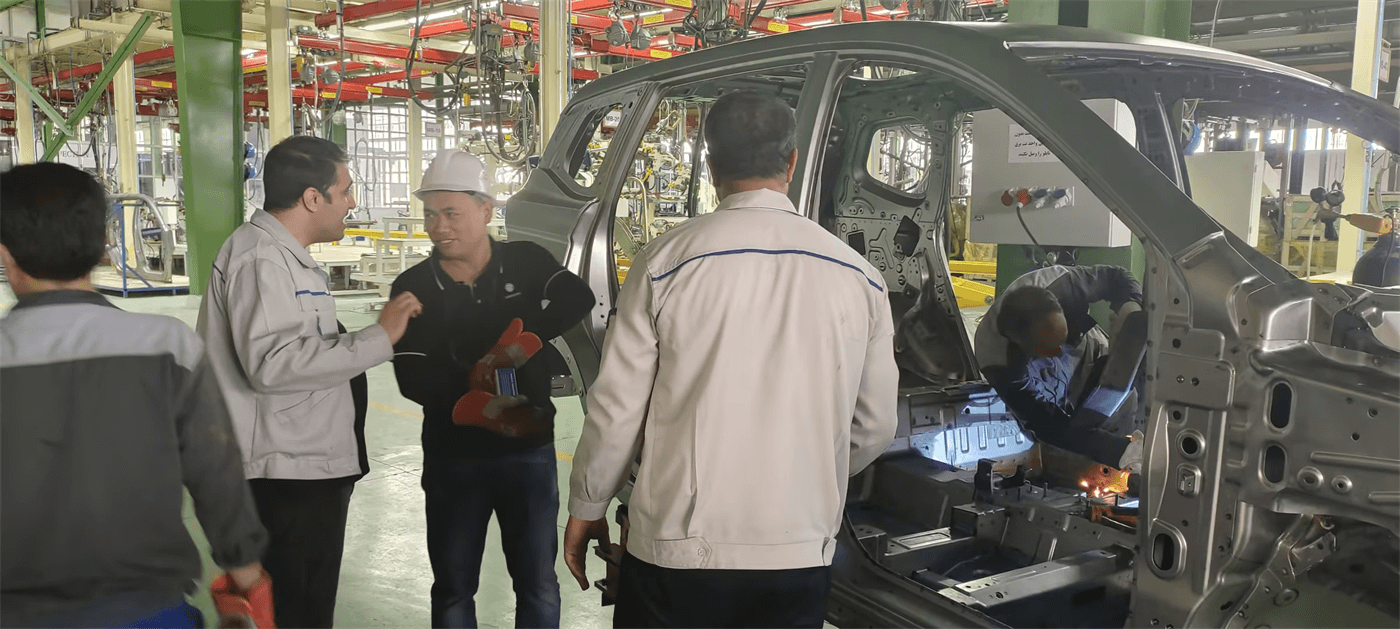

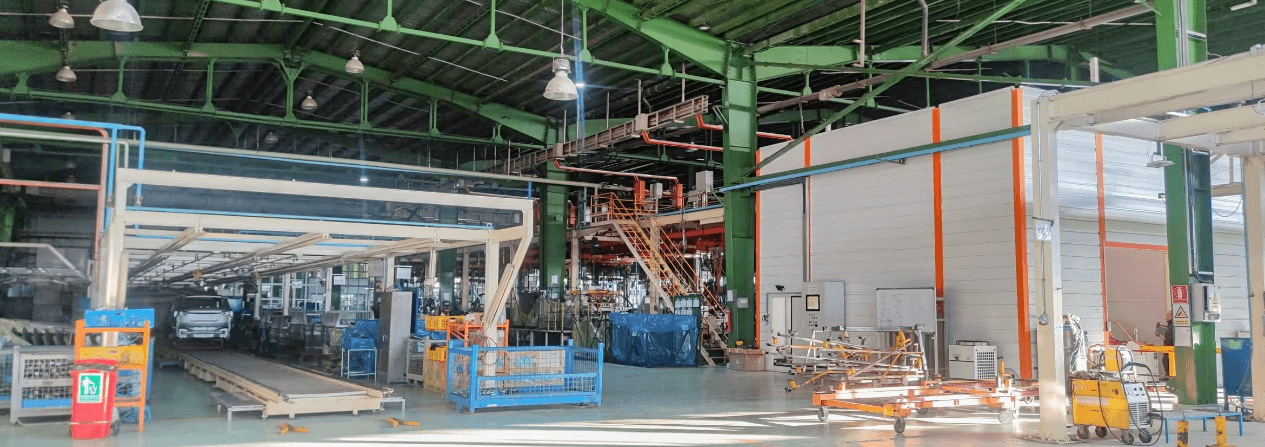

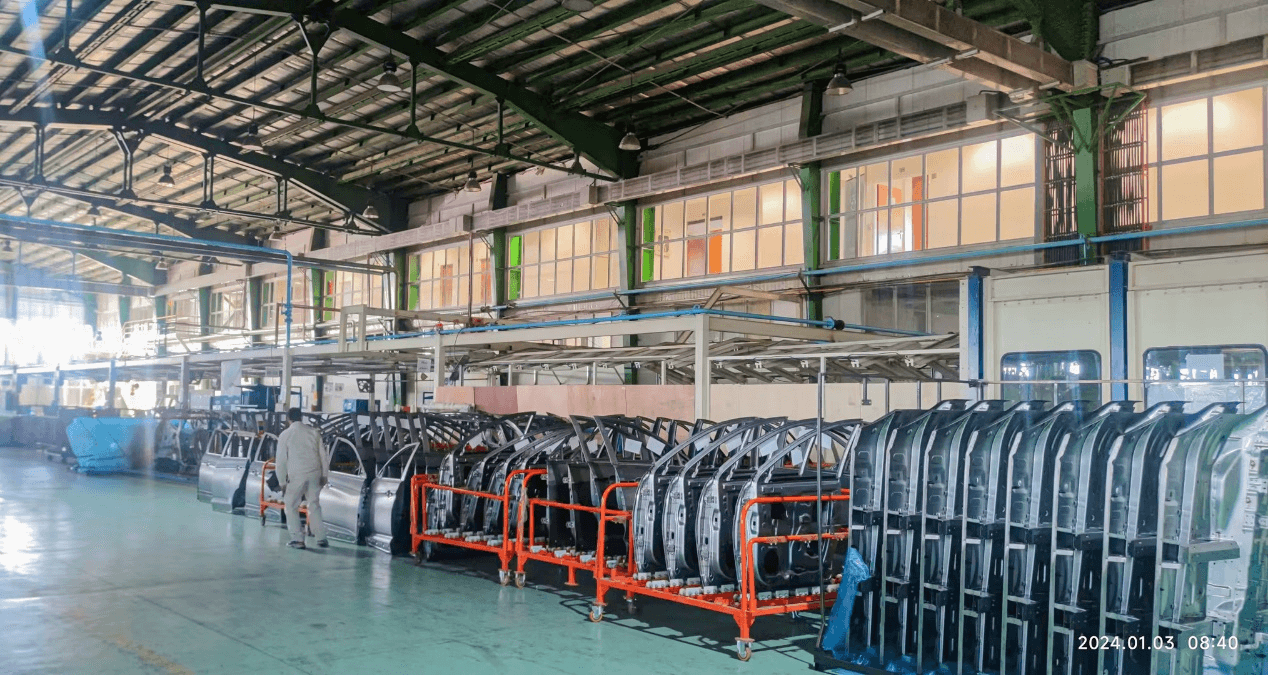

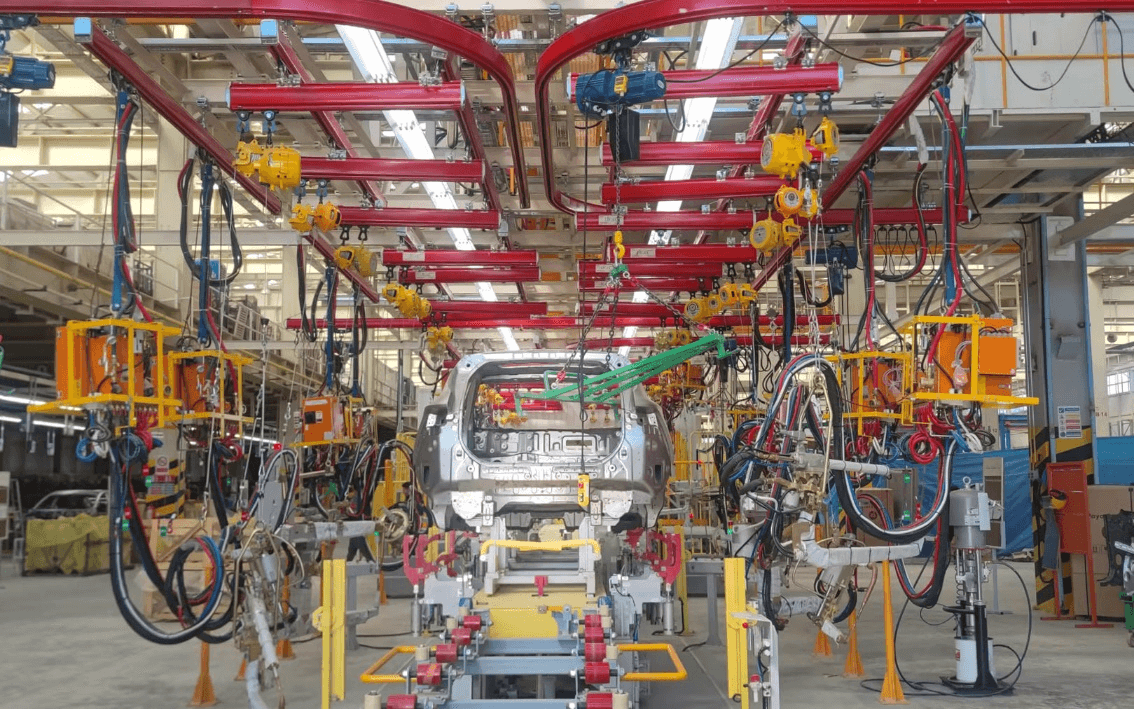

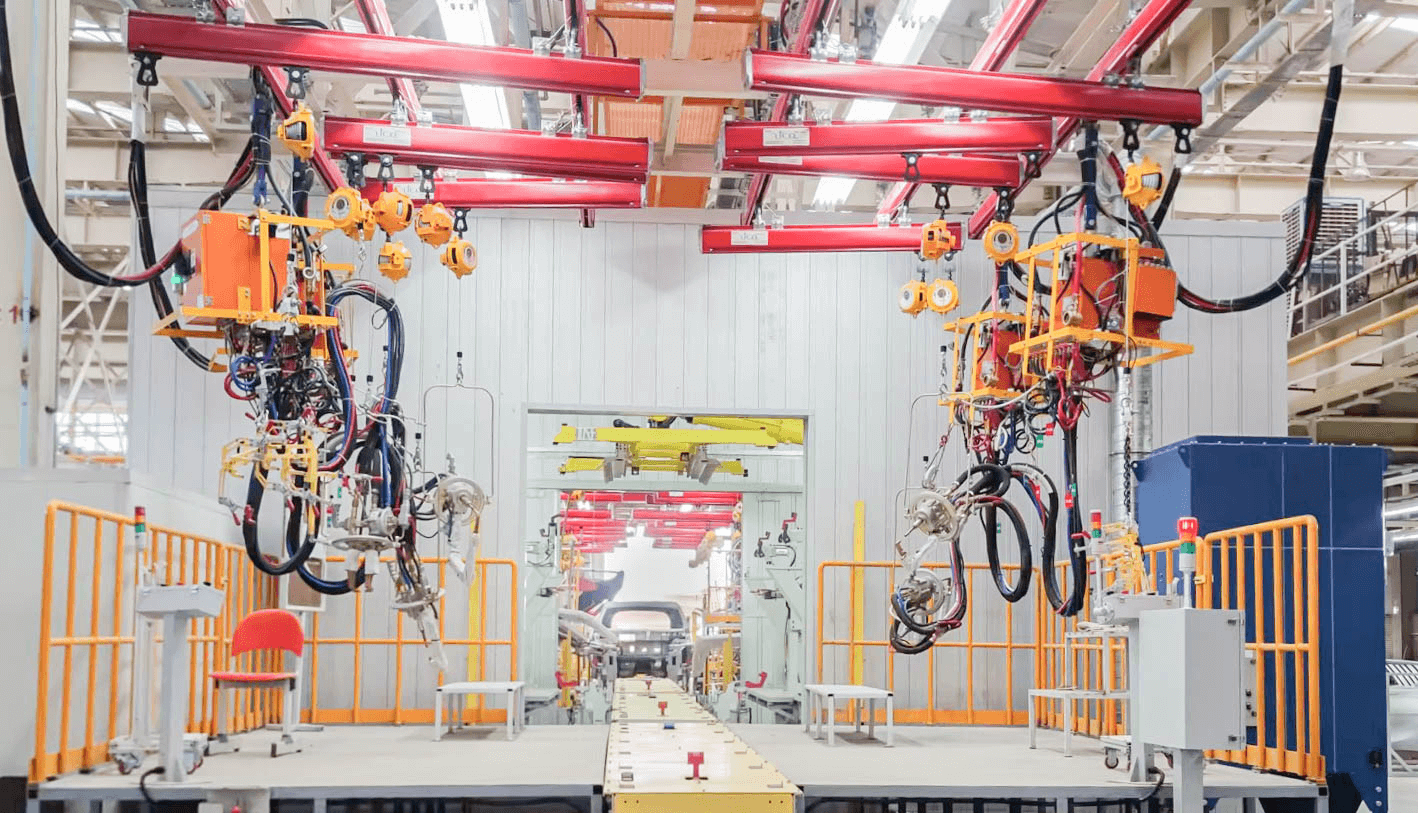

Welding Shop

|

Welding Shop Reference |

||

|

Item |

Parameter/Description |

|

|

Unit per hour (JPH) |

5 |

10 |

|

One shift production capacity (8h) |

38 |

76 |

|

Annual Production capacity (250d) |

9500 |

19000 |

|

Shop dimension (L*W)/m |

130*70 |

130*70 |

|

Line description (manual line) |

Engine compartment line, Floor line, Main line + Metal fitting line |

Engine compartment line, Floor line, Main line + Metal fitting line |

|

Shop structure |

Single floor |

Single floor |

|

Total Investment |

Total Investment = Construction investment + welding equipment investment + jigs and fixtures investment | |

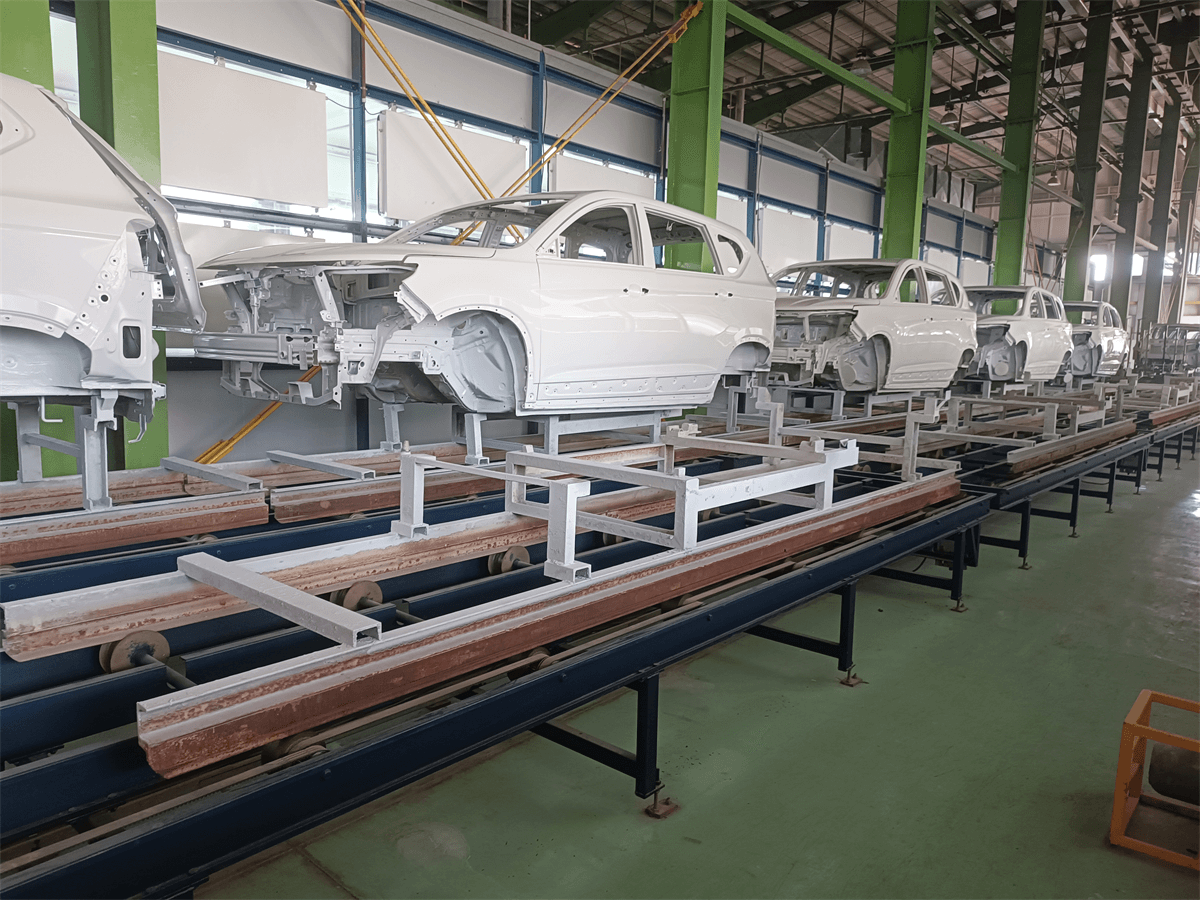

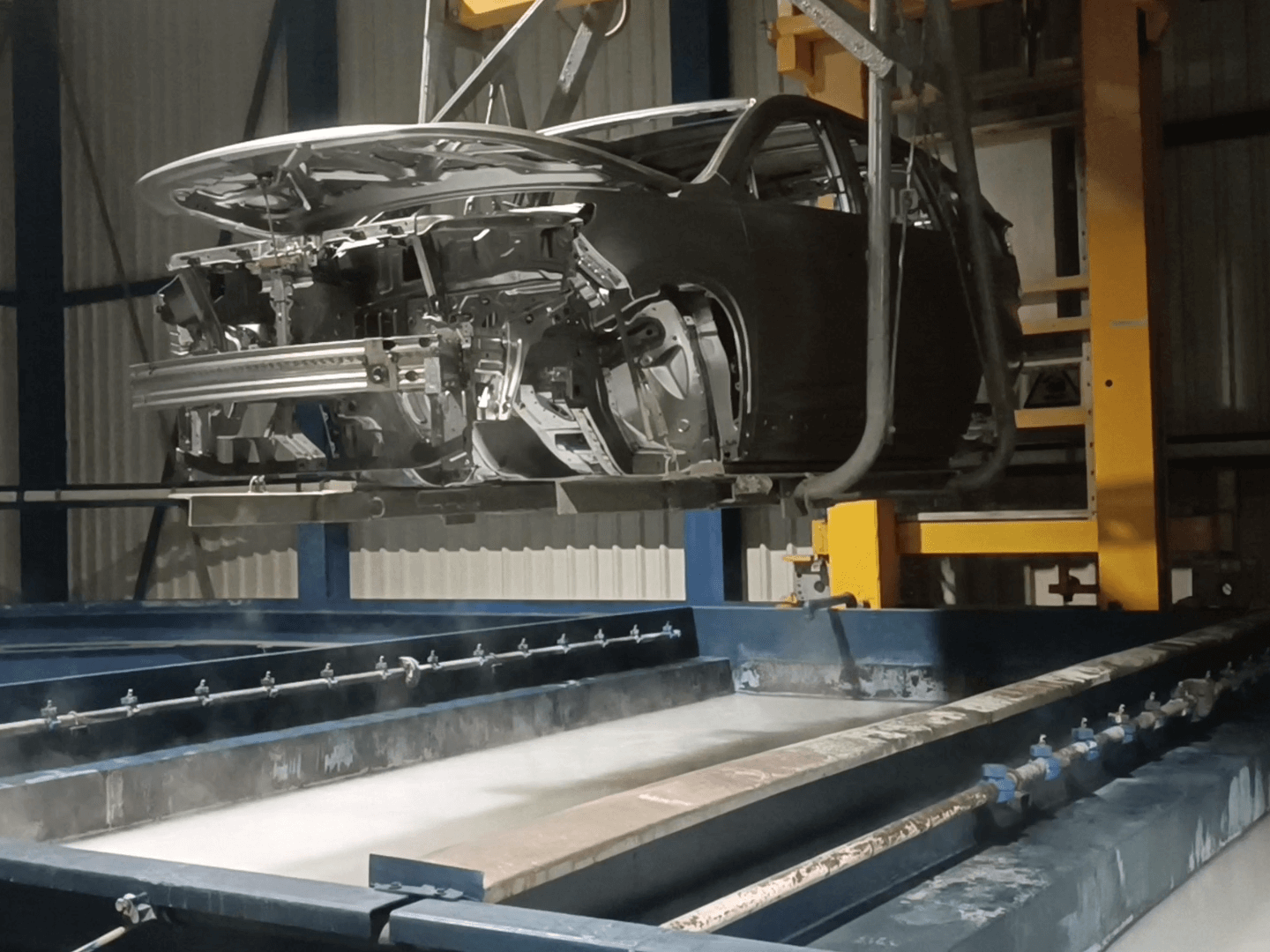

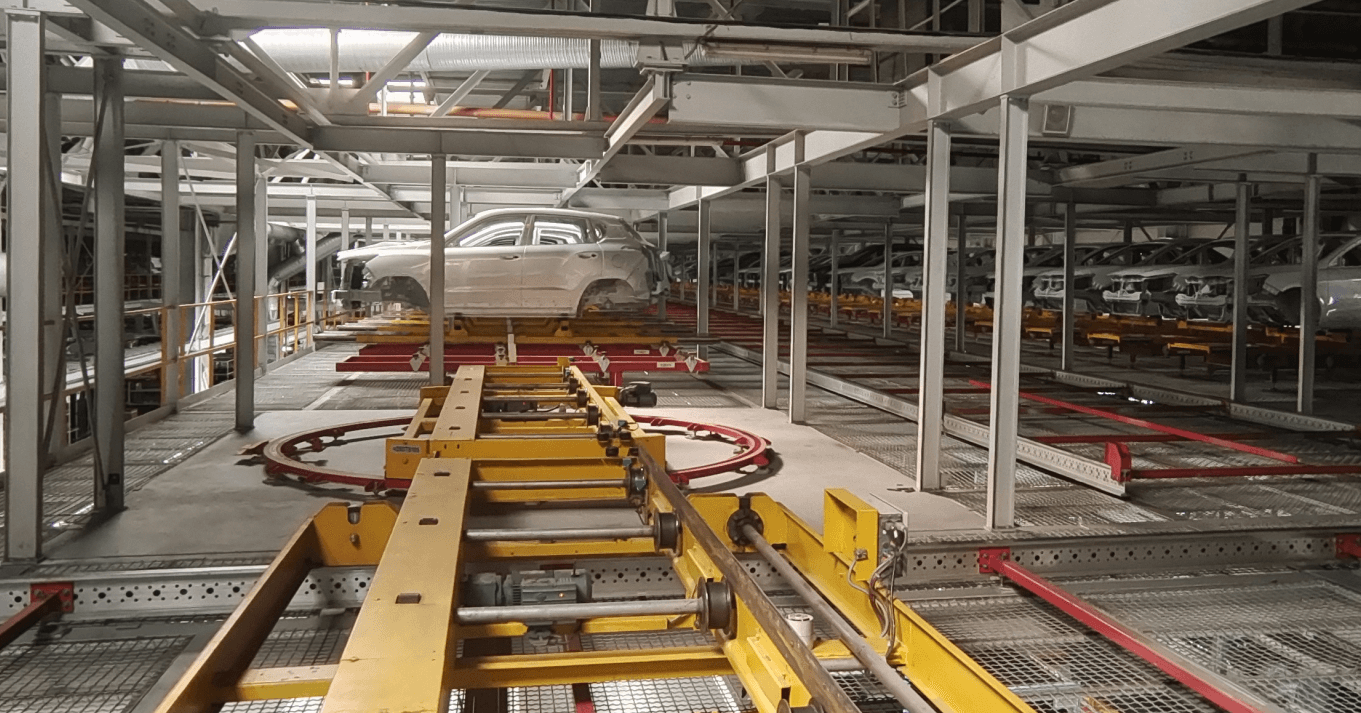

Painting shop

|

Painting Shop Reference |

|||||

|

Item |

Parameter/Description |

||||

|

Unit per hour (JPH) |

5 |

10 |

20 |

30 |

40 |

|

One shift production capacity (8h) |

40 |

80 |

160 |

240 |

320 |

|

Annual production capacity (250d) |

10000 |

20000 |

40000 |

60000 |

80000 |

|

Shop dimension (L*W) |

120*54 |

174*66 |

224*66 |

256*76 |

320*86 |

|

Shop Structure |

Single floor |

Single floor |

2 floors |

2 floors |

3 floors |

|

Building area (㎡) |

6480 |

11484 |

14784 |

19456 |

27520 |

|

Pre-treatment & ED type |

Step-by-step |

Step-by-step |

Step-by-step |

Continuous |

Continuous |

|

Primer/color/clear paint |

Manual spraying |

Manual spraying |

Robotic spraying |

Robotic spraying |

Robotic spraying |

|

Total Investment |

Total Investment = Equipment investment +Construction investment |

||||

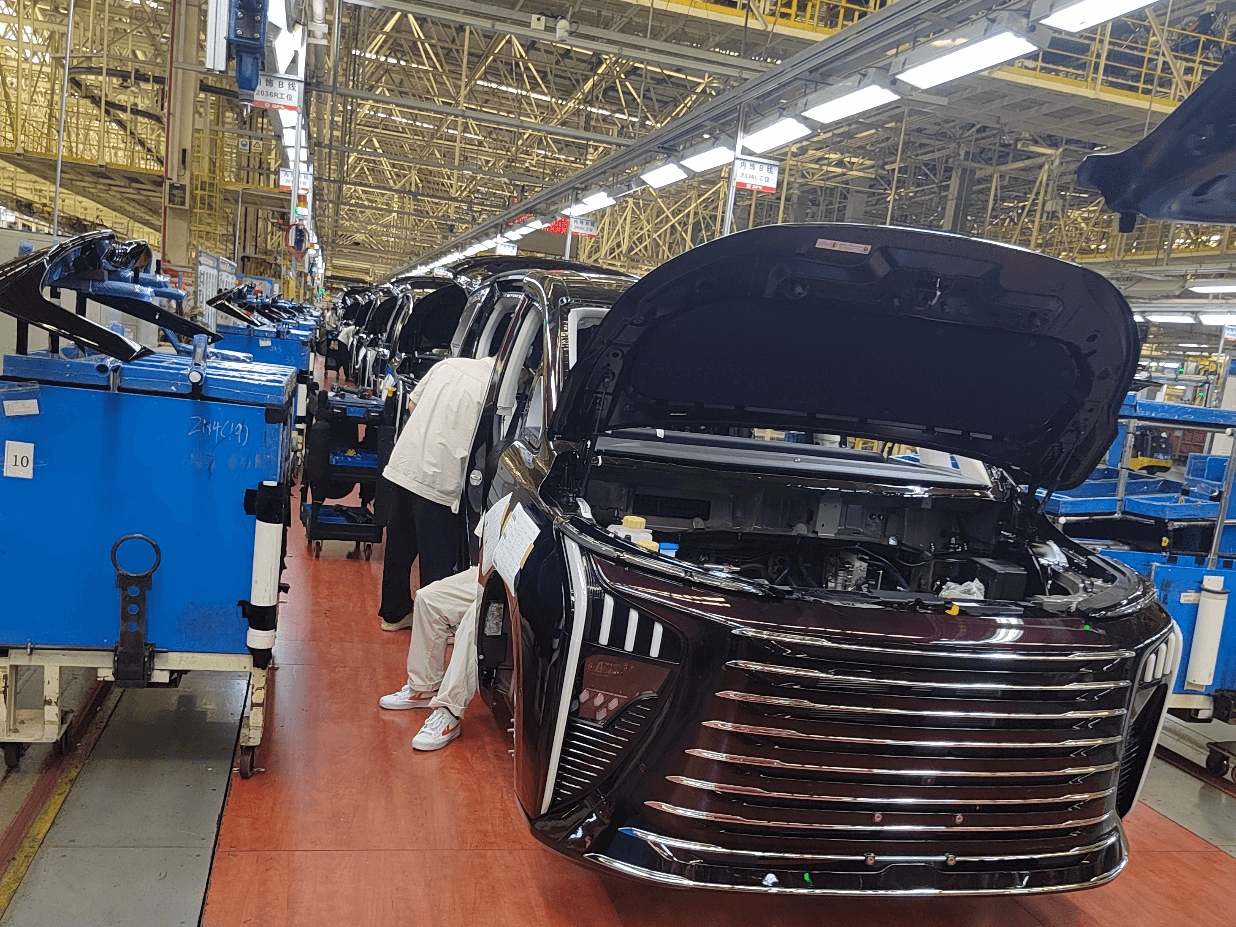

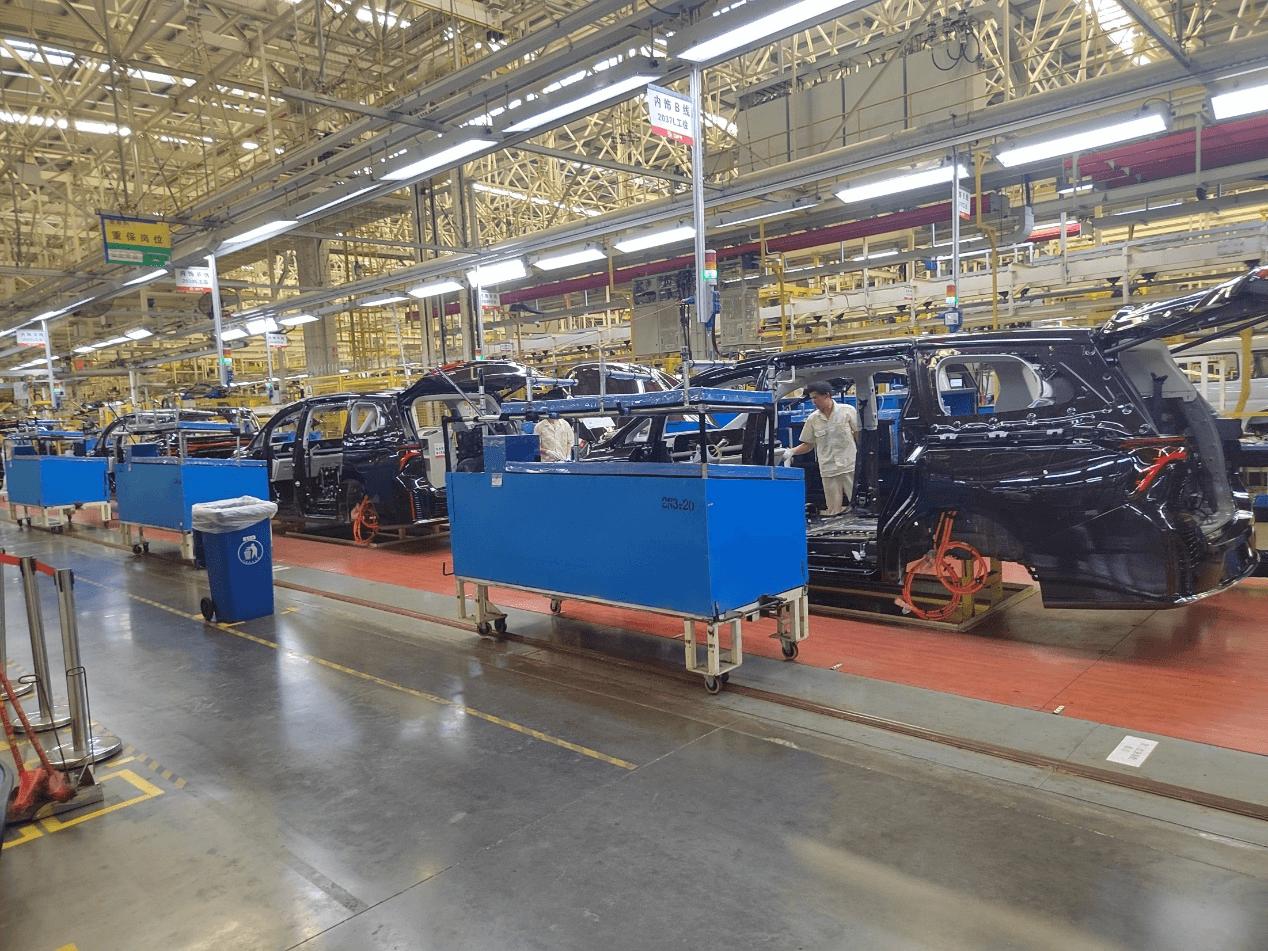

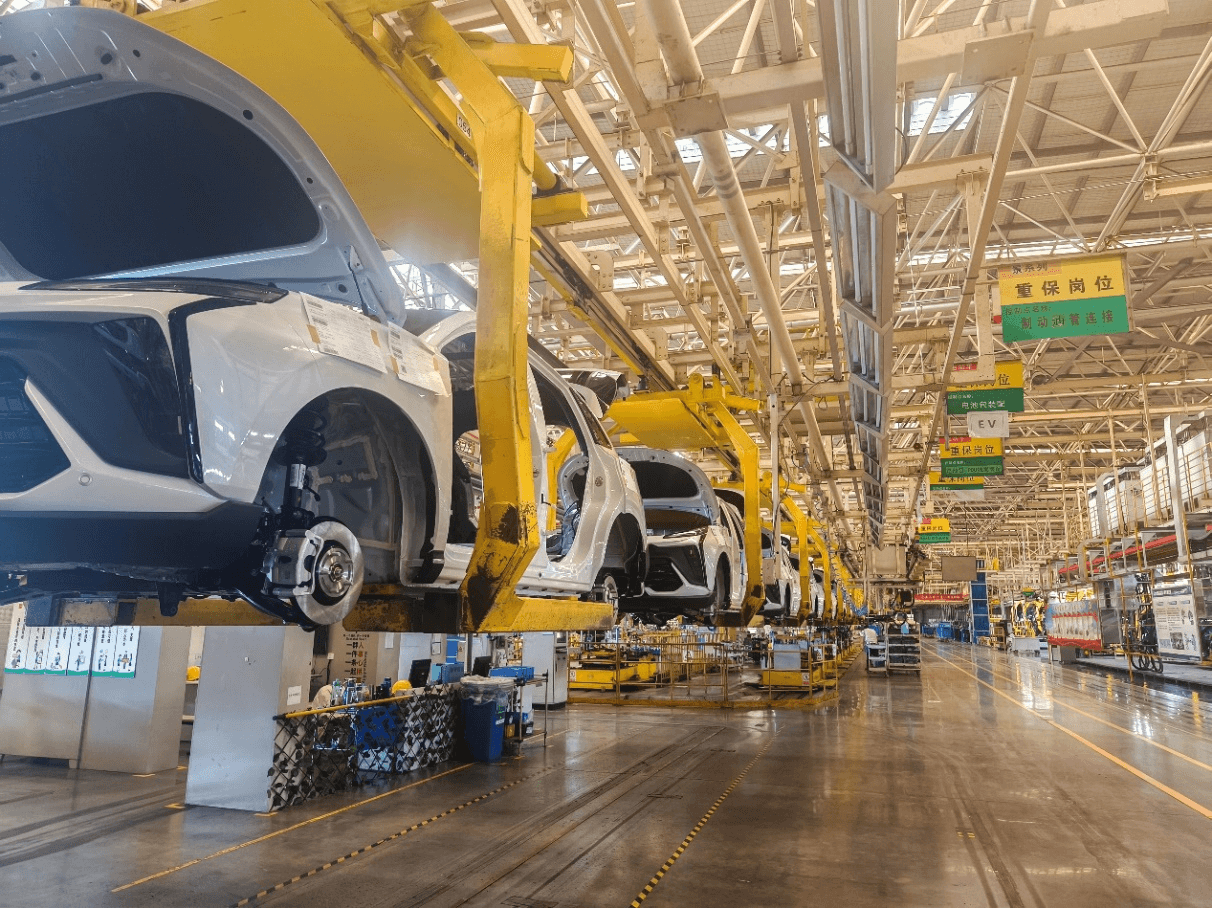

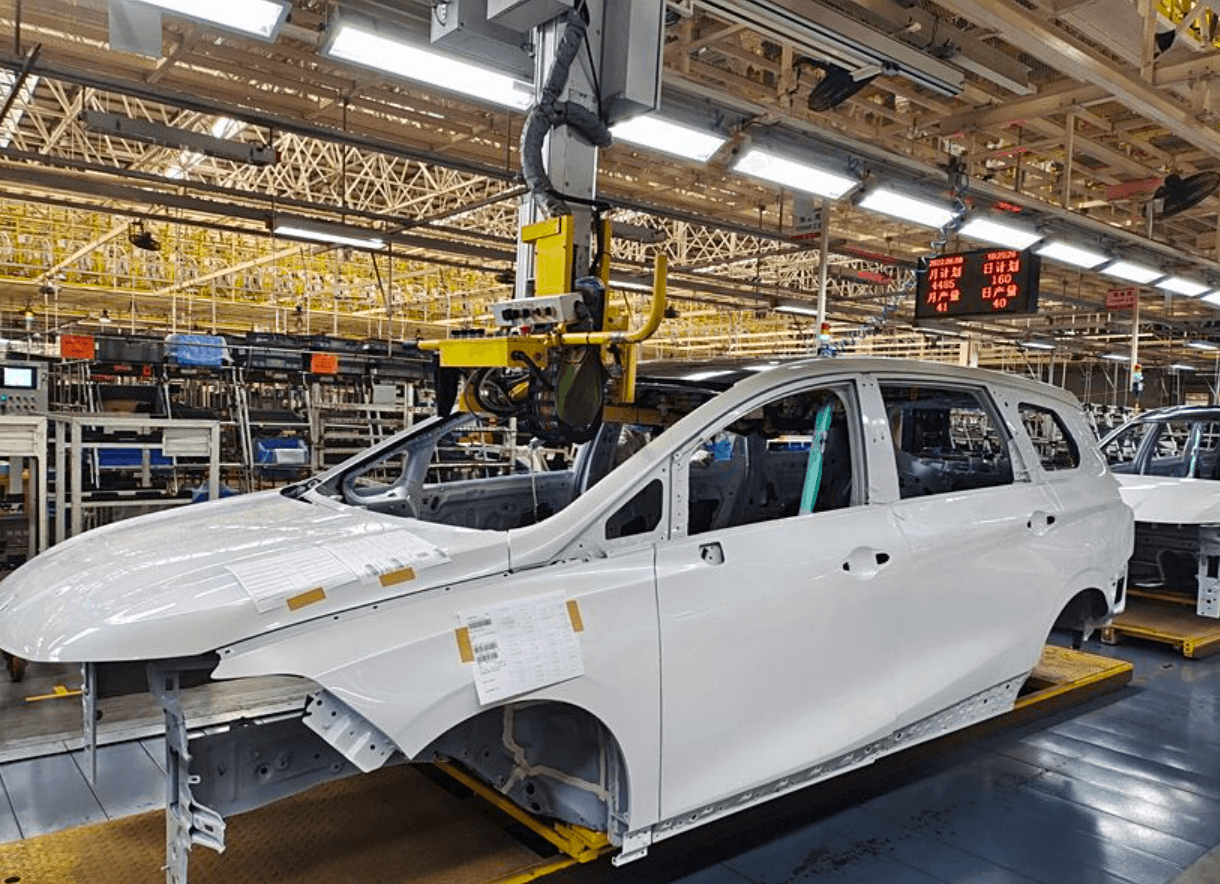

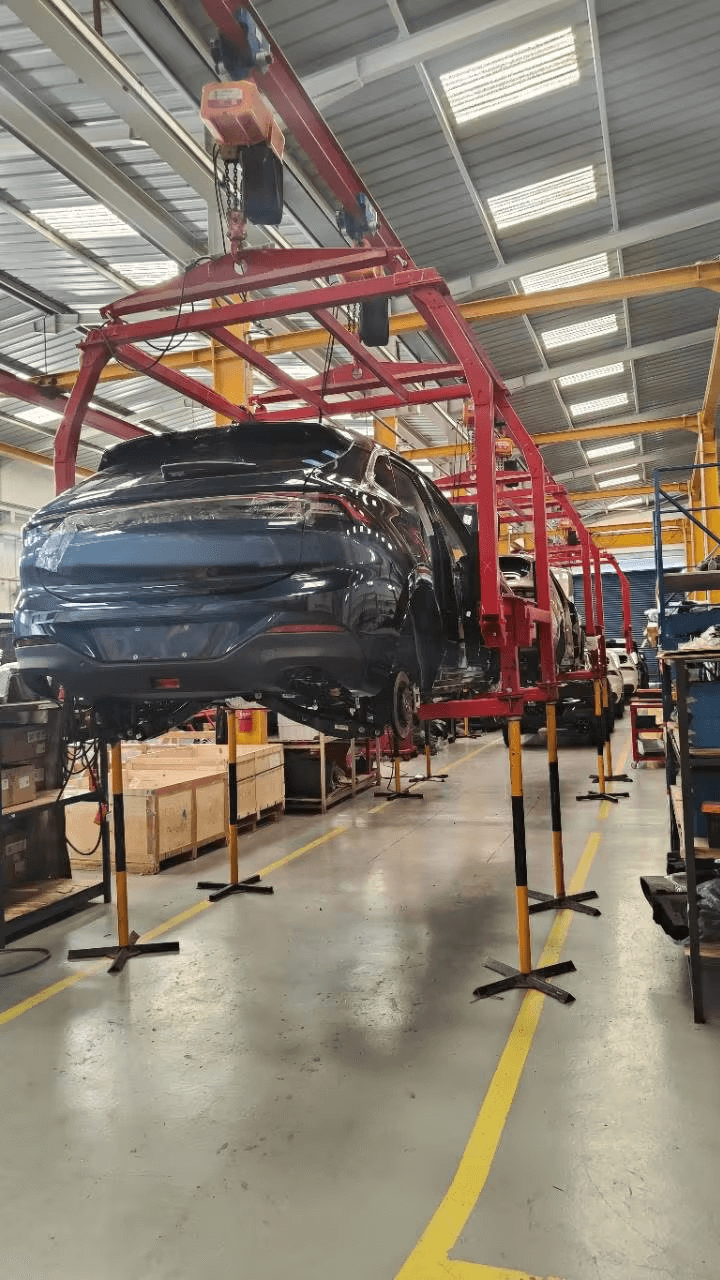

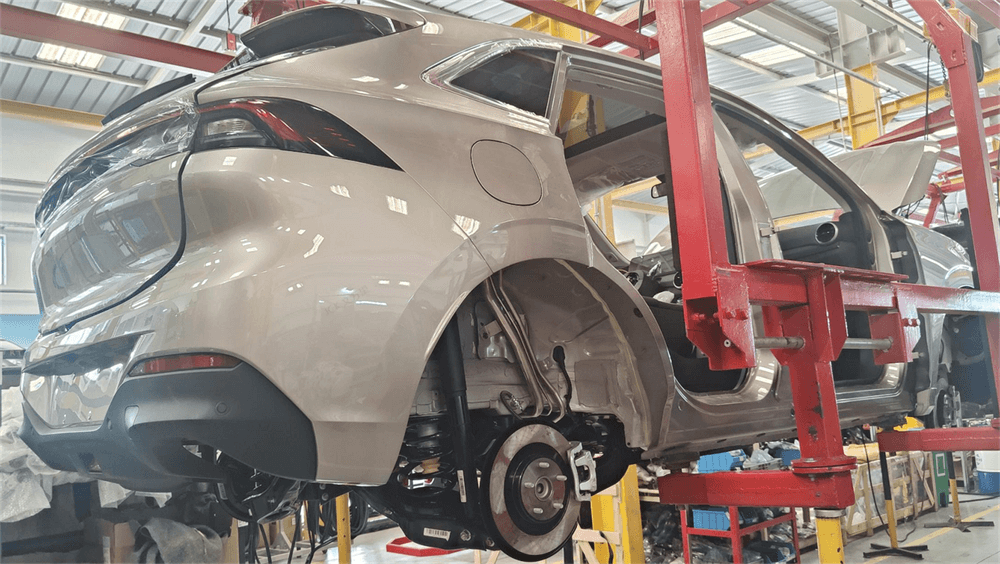

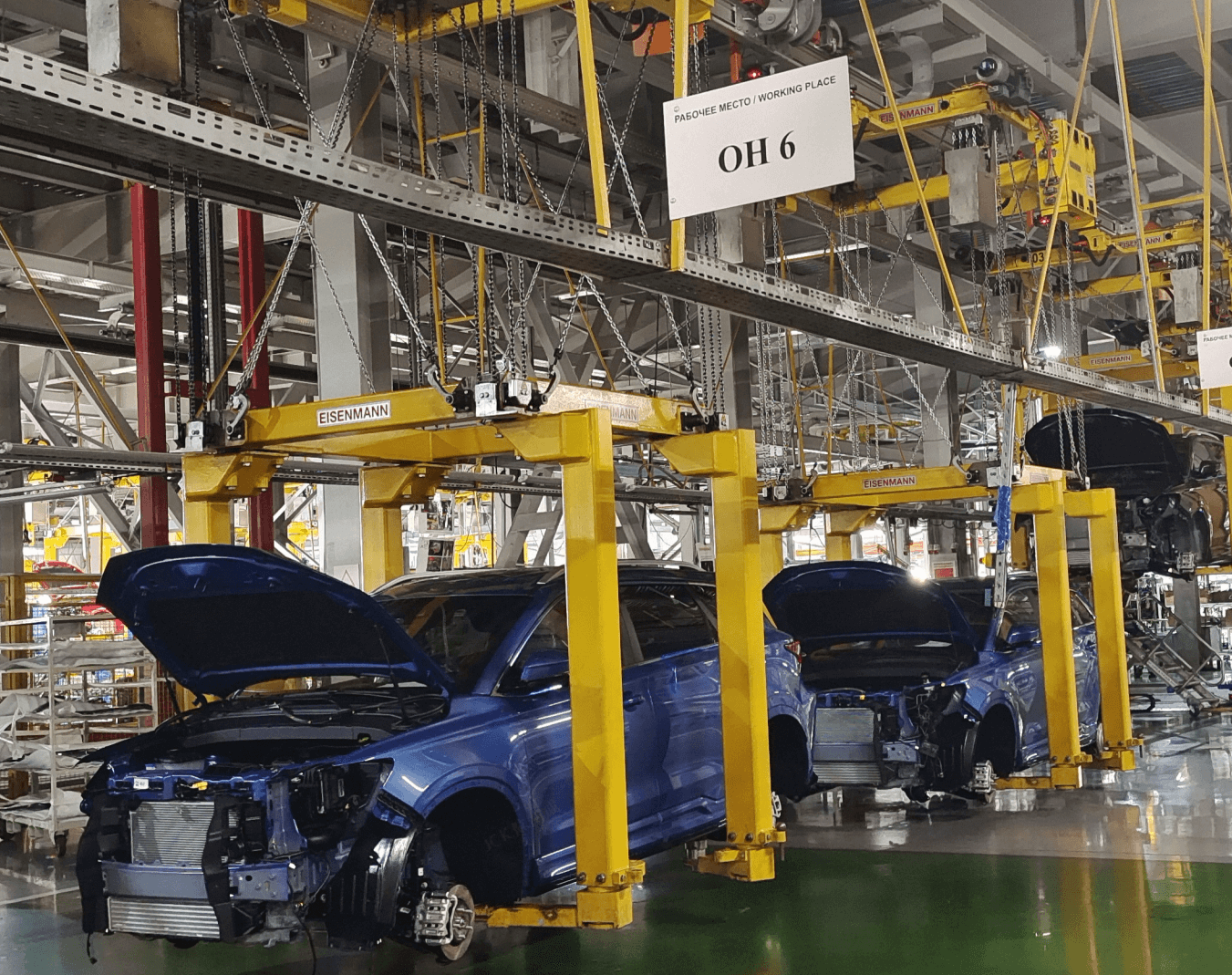

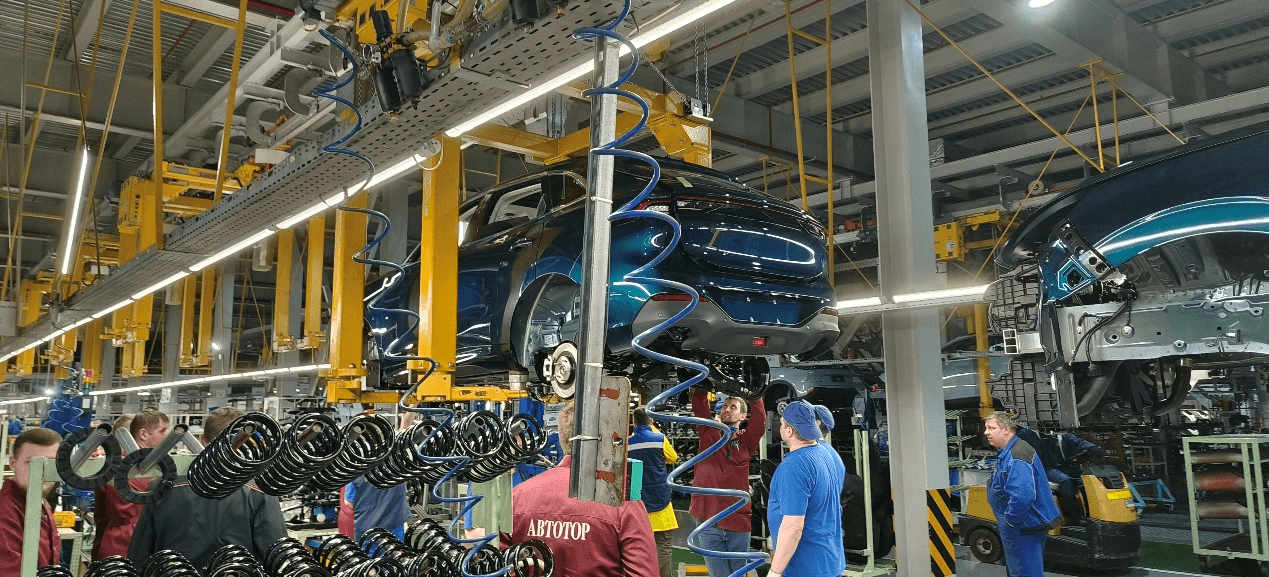

Assembly shop

Trim Line

Underbody Line

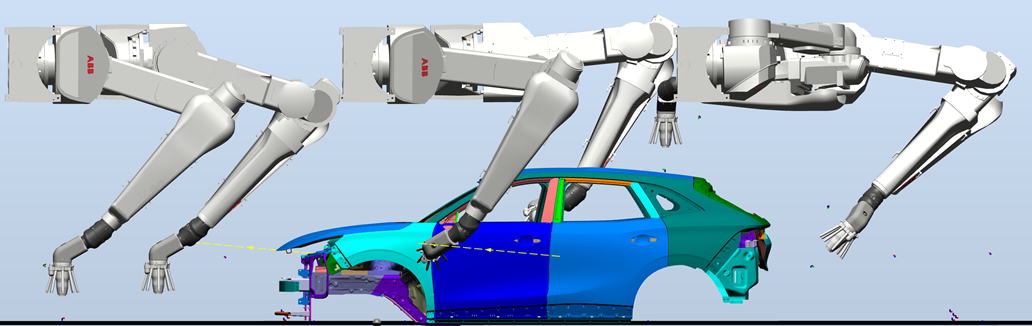

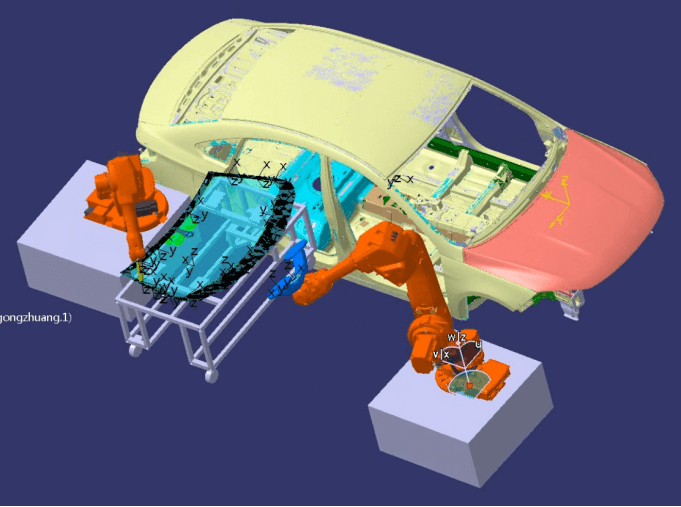

Front Windshield Robot-Assembling Station

Panoramic Sunroof Robot-Assembling Station

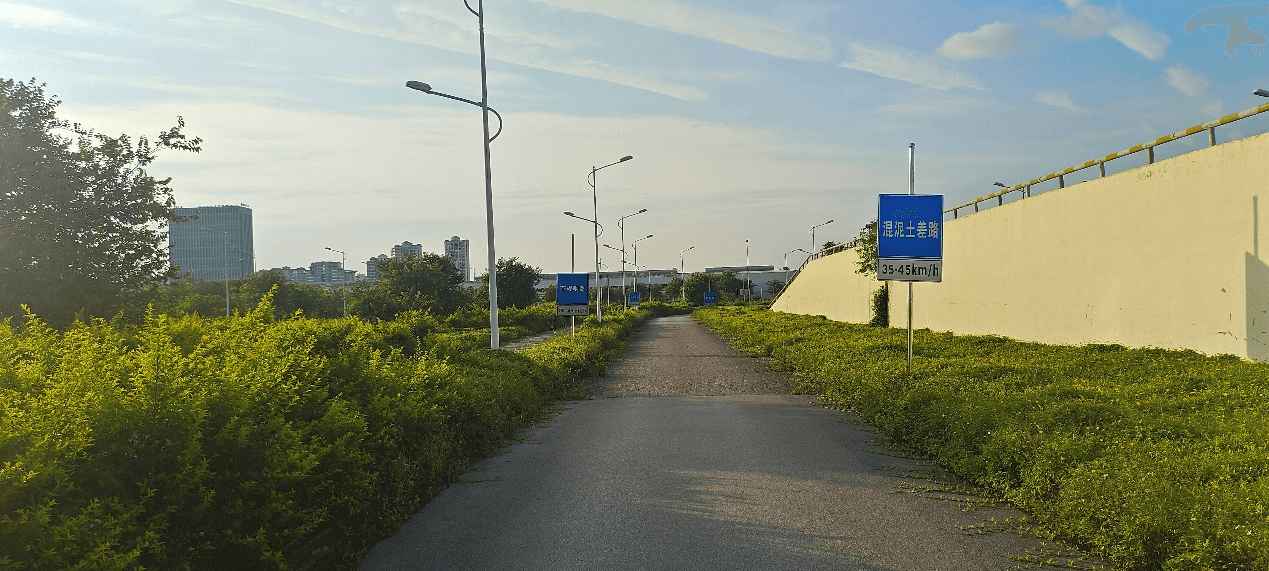

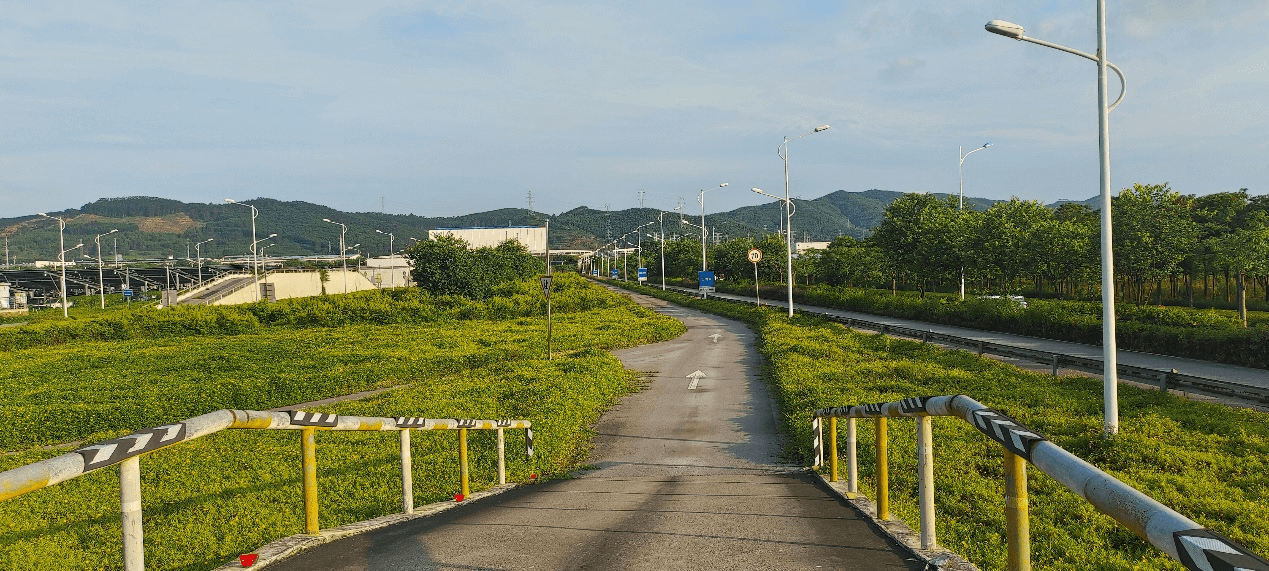

Test Road

|

Assembly Shop Reference |

||||

|

Item |

Parameter/Description |

|||

|

Unit per hour (JPH) |

0.6 |

1.25 |

5 |

10 |

|

One shift production capacity (8h) |

5 |

10 |

40 |

80 |

|

Annual production capacity (2000h) |

1200 |

2500 |

10000 |

20000 |

|

Shop Size (L*W) |

100*24 |

80*48 |

150*48 |

256*72 |

|

Assembly shop area (㎡) |

2400 |

3840 |

7200 |

18432 |

|

Warehouse area |

/ |

2500 |

4000 |

11000 |

|

Test road area |

/ |

/ |

20000 |

27400 |

|

Total Investment |

Total Investment = Construction investment + Equipment investment |

|||

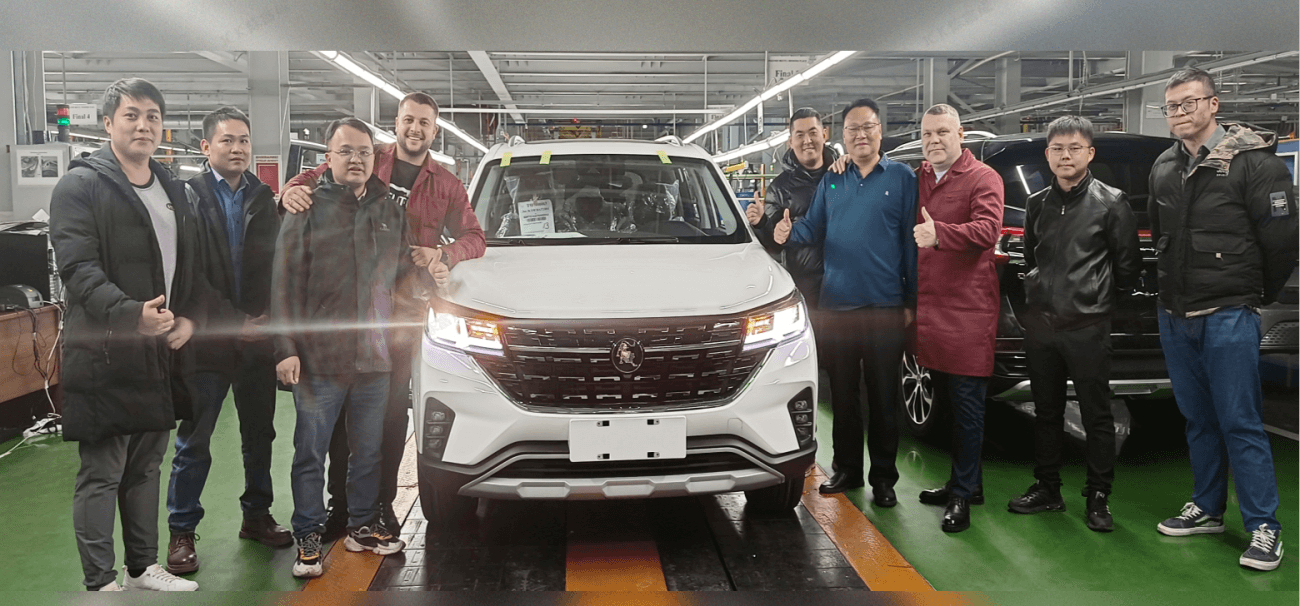

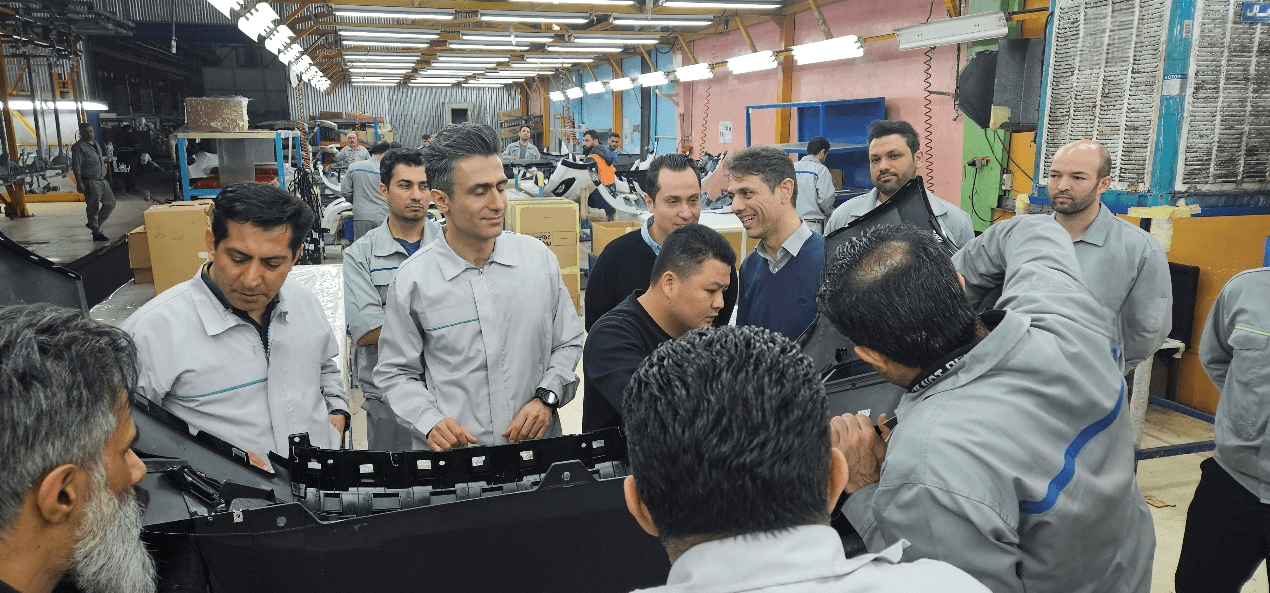

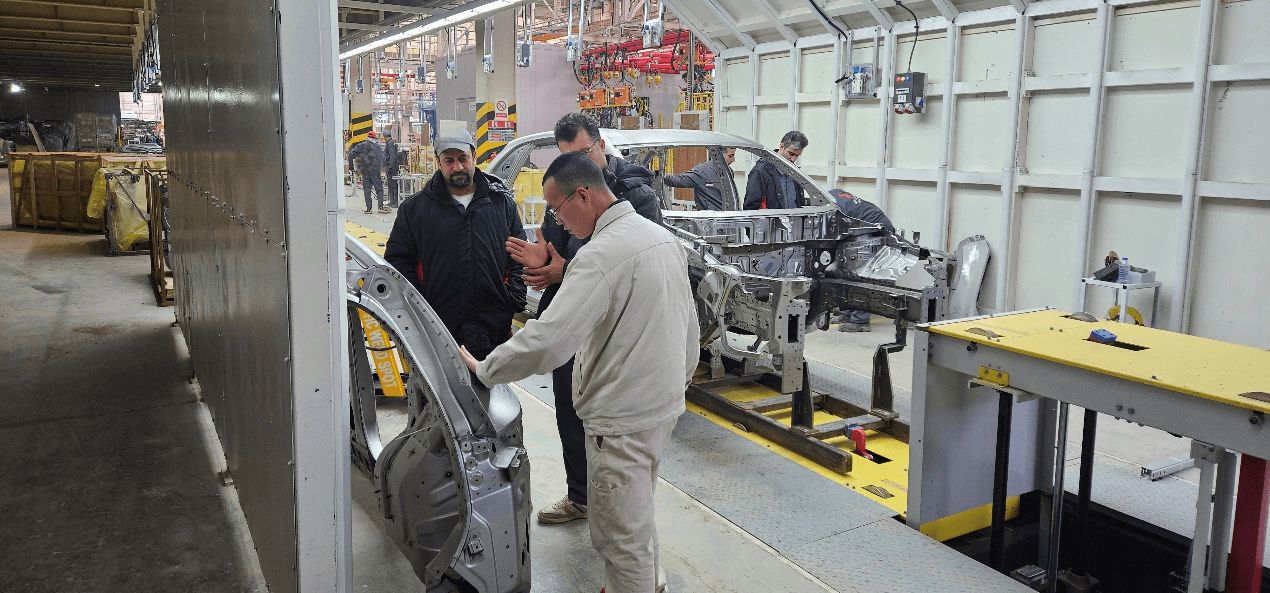

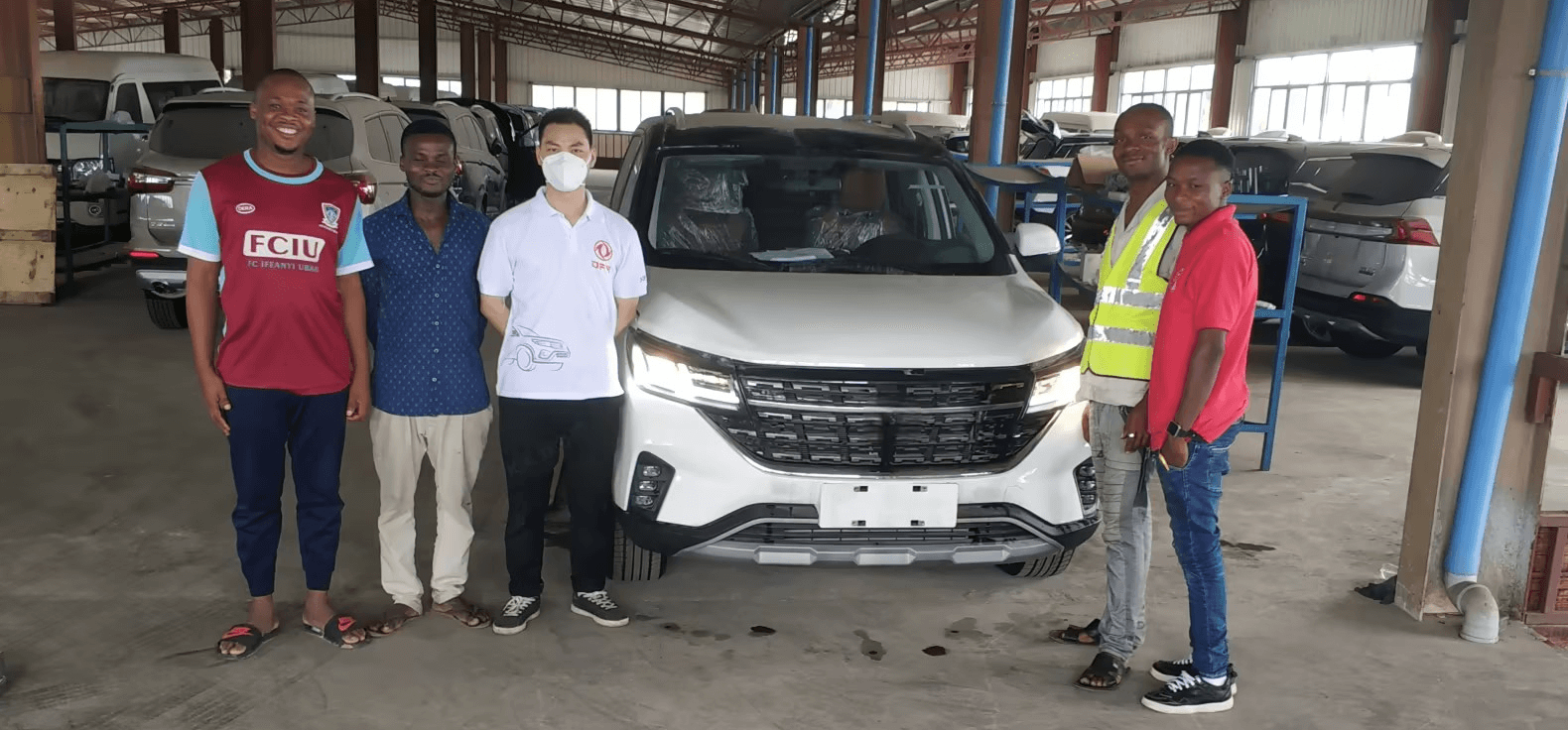

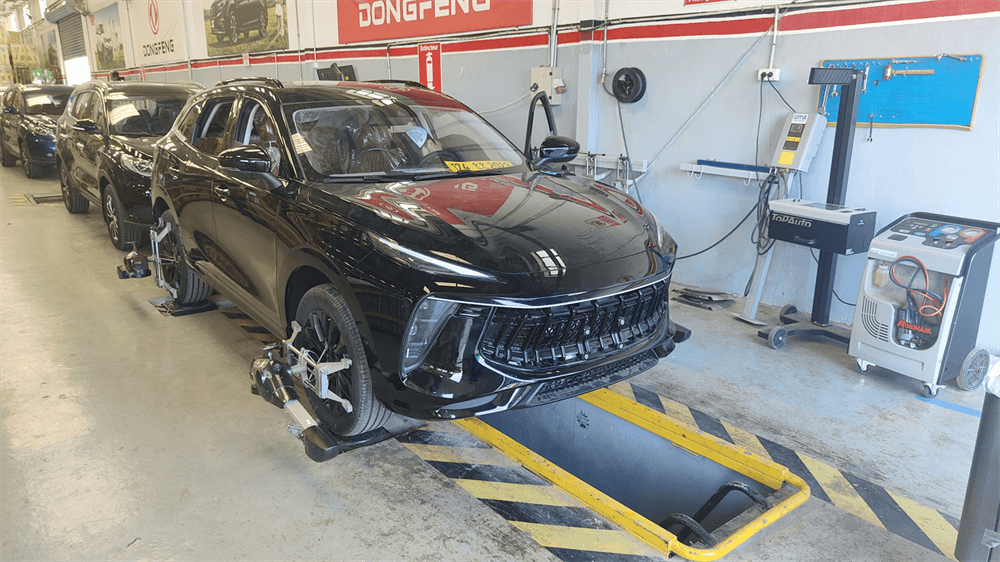

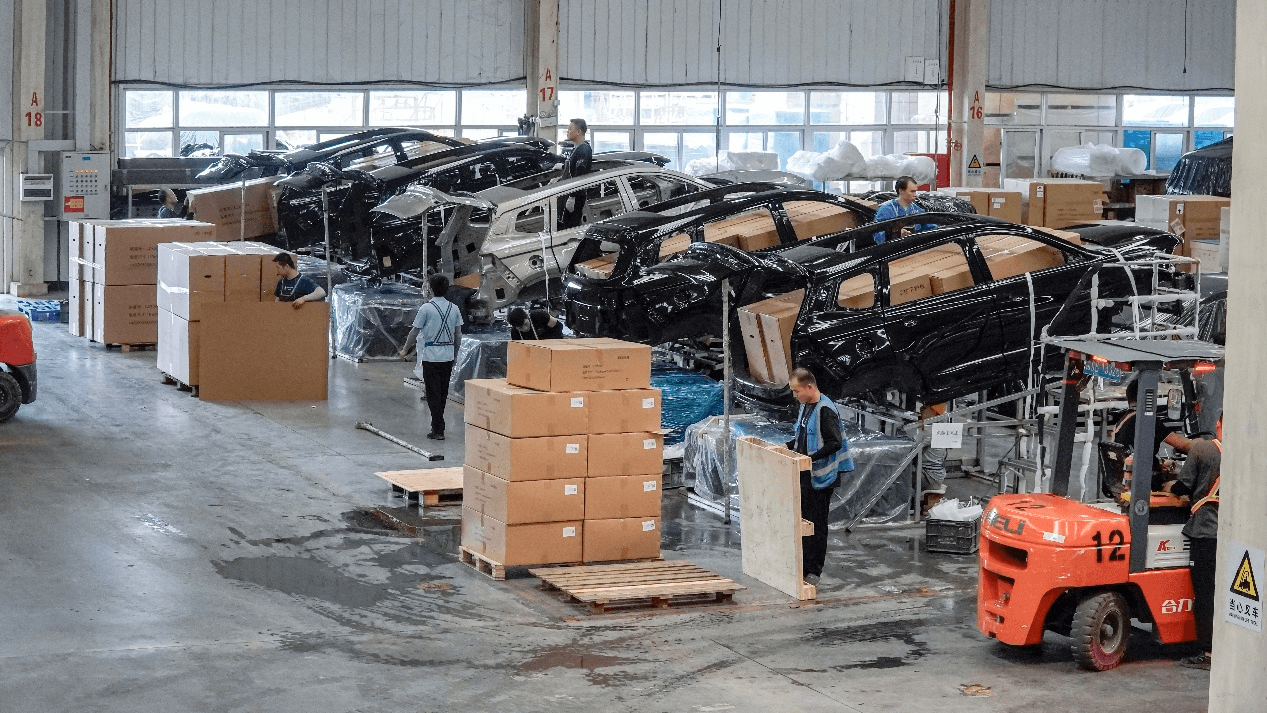

Overseas Loading Guidance

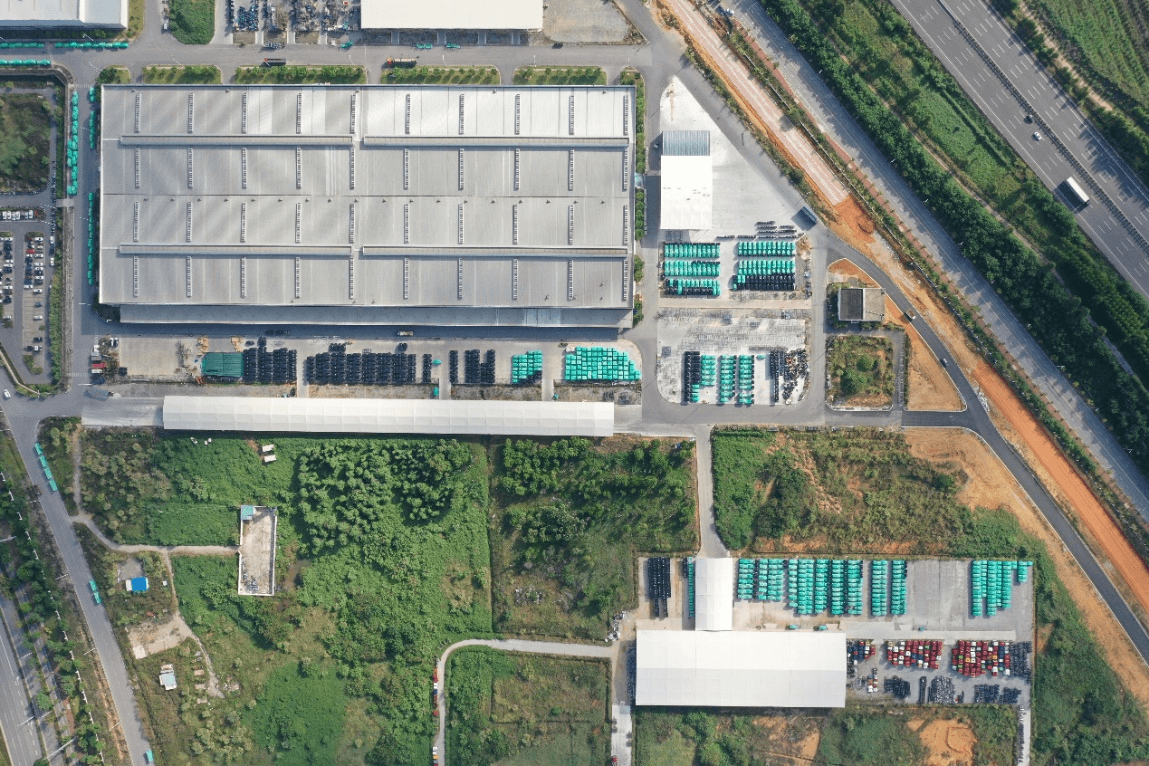

Glimpse of DFLZ Overseas Factories

Middle East CKD Factory for Passenger Vehicles

CKD Factory

Painting Shop

Welding Shop

Assembly Shop

Middle East SKD Factory for Commercial Vehicles

Assembly Shop

Chassis Line

Engine Line

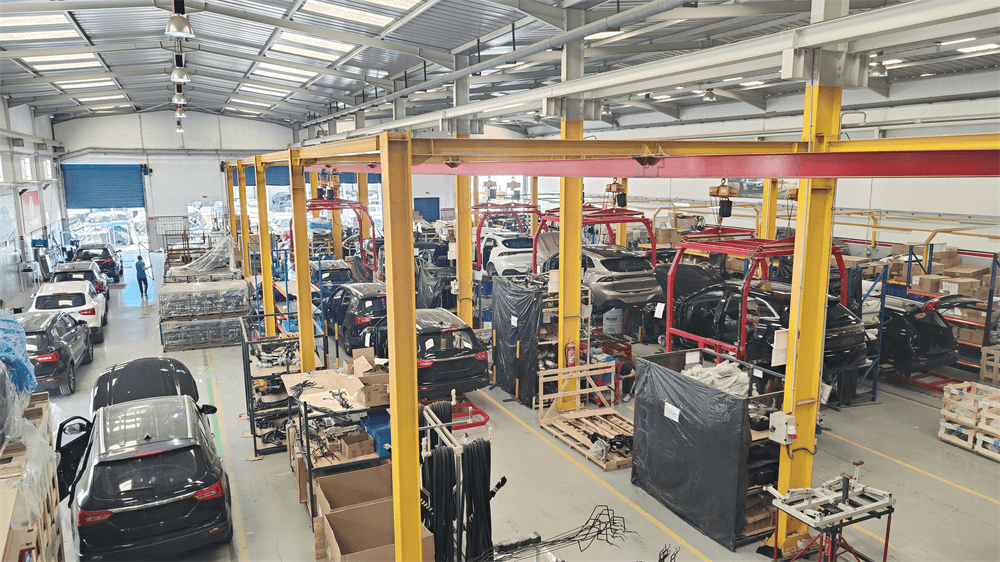

North Africa SKD Factory for Passenger Vehicles

Assembly Shop

Low-Cost Underbody Line

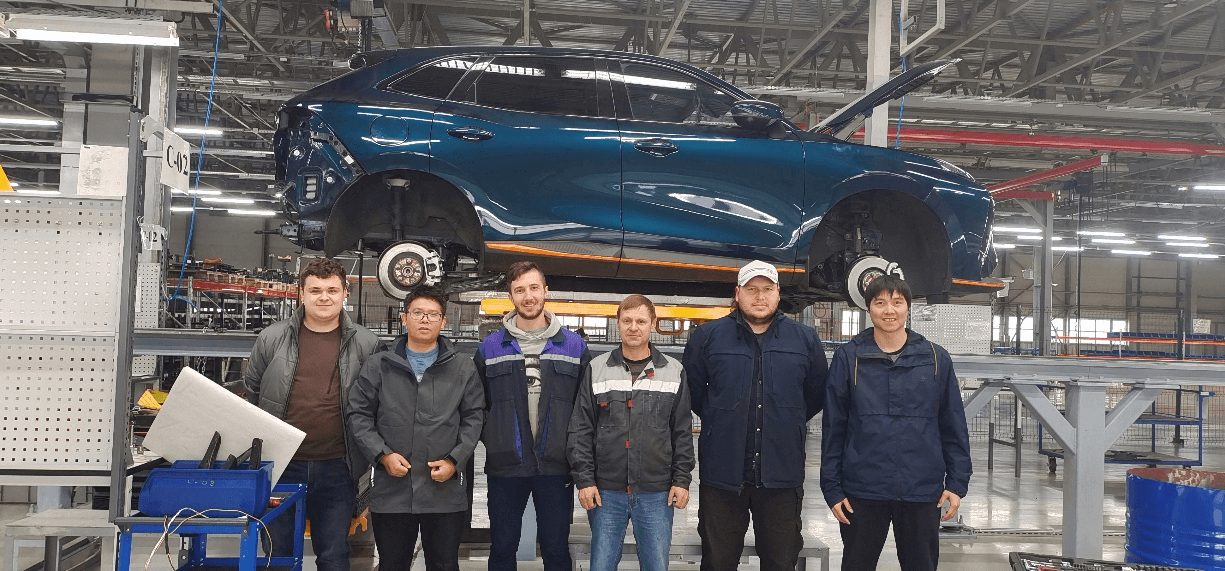

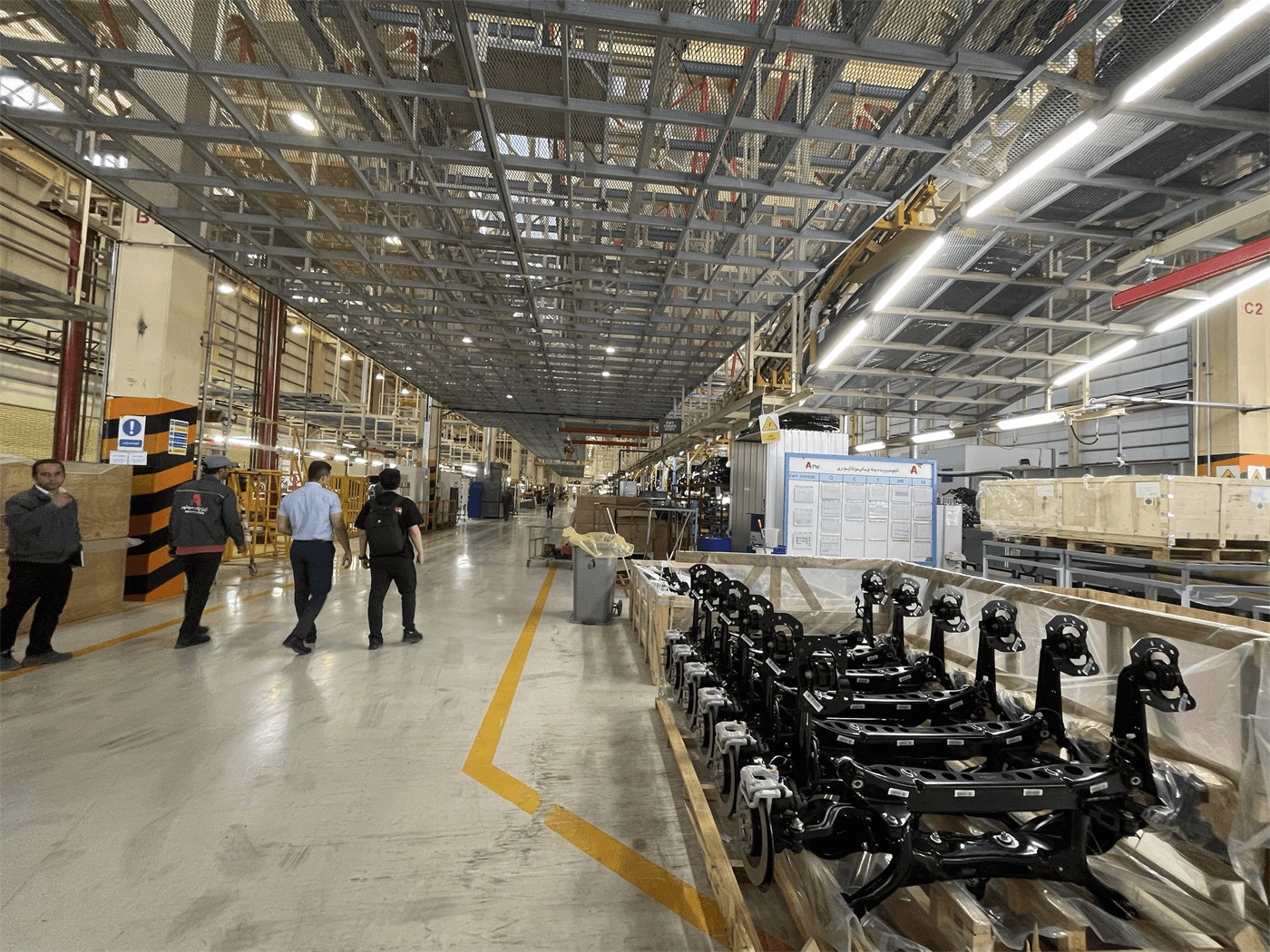

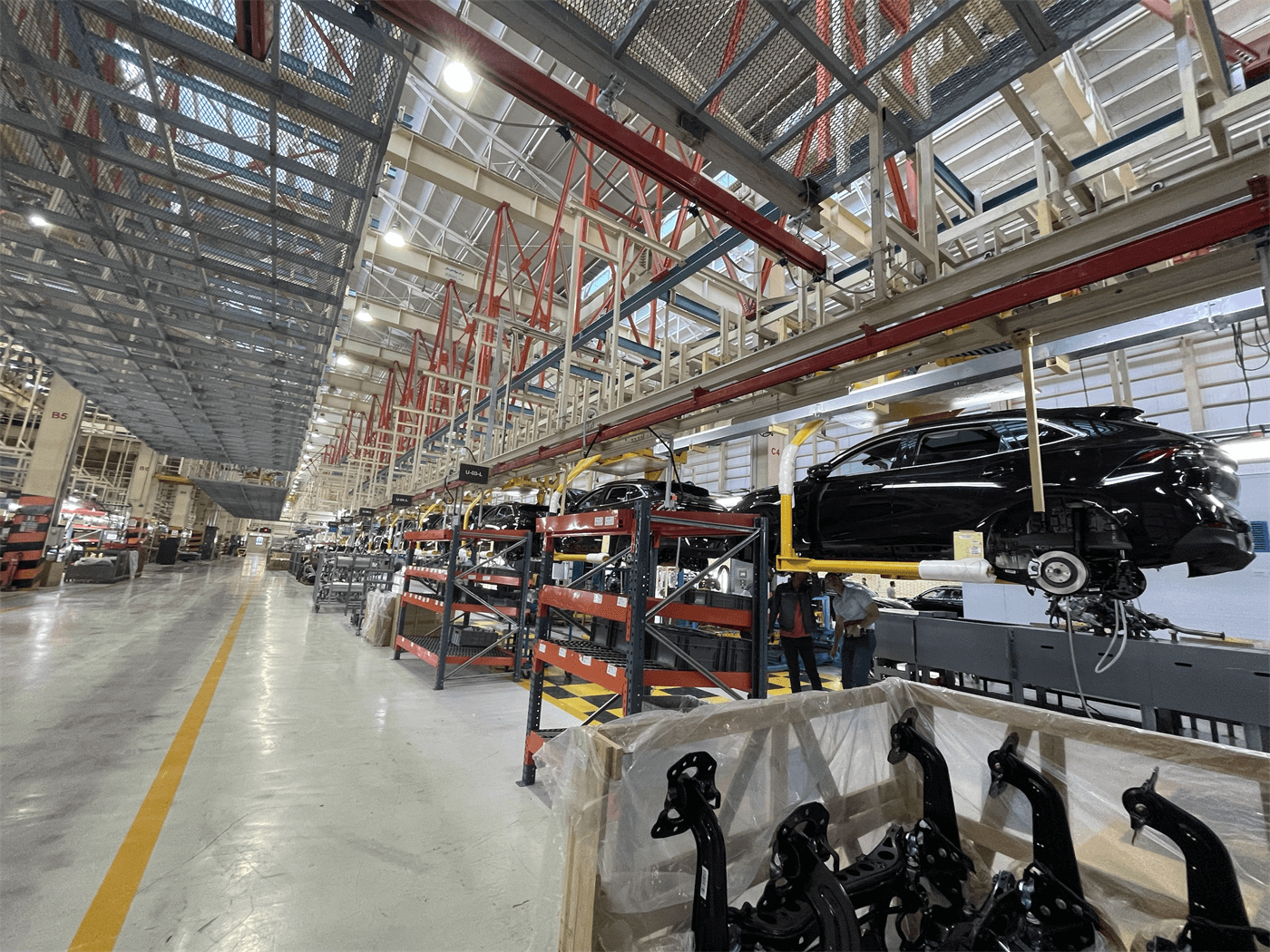

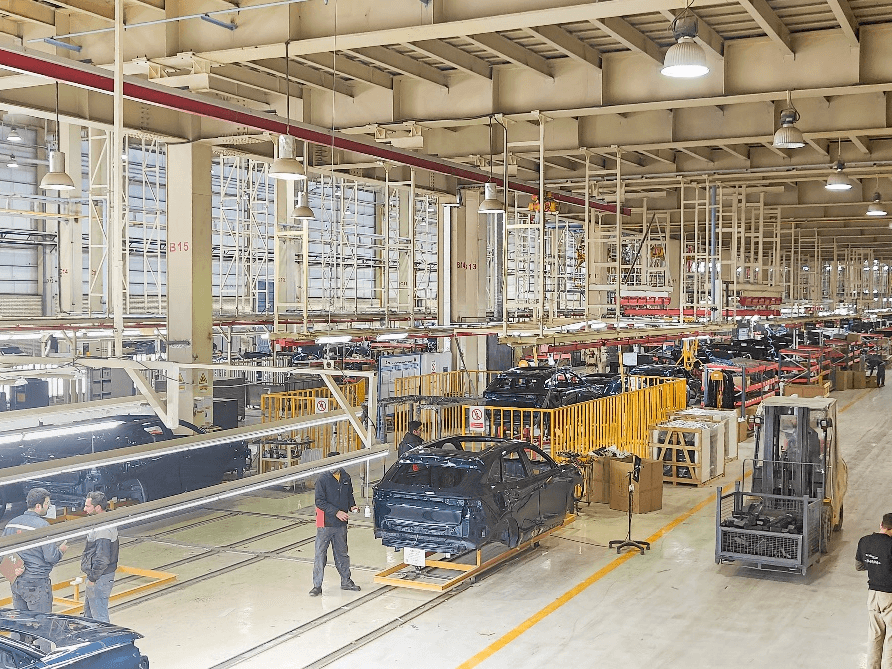

Central Asia CKD Factory for Passenger Vehicles

Aerial View

Body In White Feeding Area

Trim Line

Final Line

Underbody Line

DFLZ KD Workshop

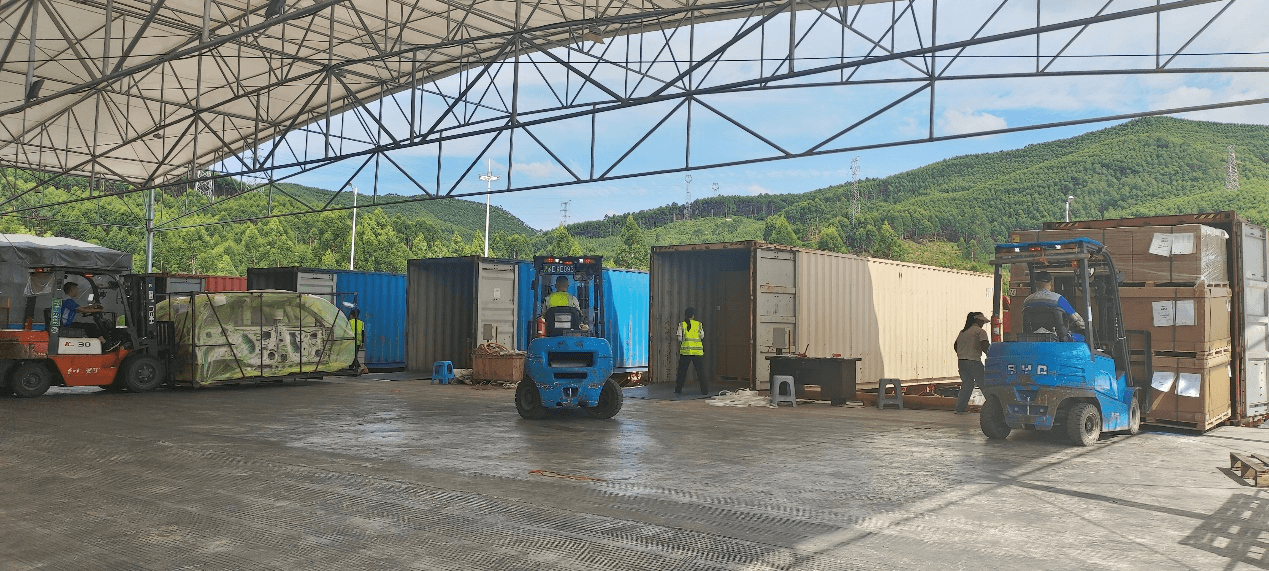

DFLZ KD workshop is located in the Commercial Vehicle Base, covering an area of 45000㎡, it can meets the packing of 60, 000 units (sets) of KD parts per year; We have 8 container loading platforms and a daily loading capacity of 150 containers.

Aerial View

Full-Time Monitoring

Container Loading Platform

Professional KD Packing

KD Packing Team

A team of more than 50 people, including packing designers, packing operators, testing engineers, equipment maintenance engineers, digitization engineers, and coordination personnel.

More than 50 packing design patents and participation in industry standard formulation.

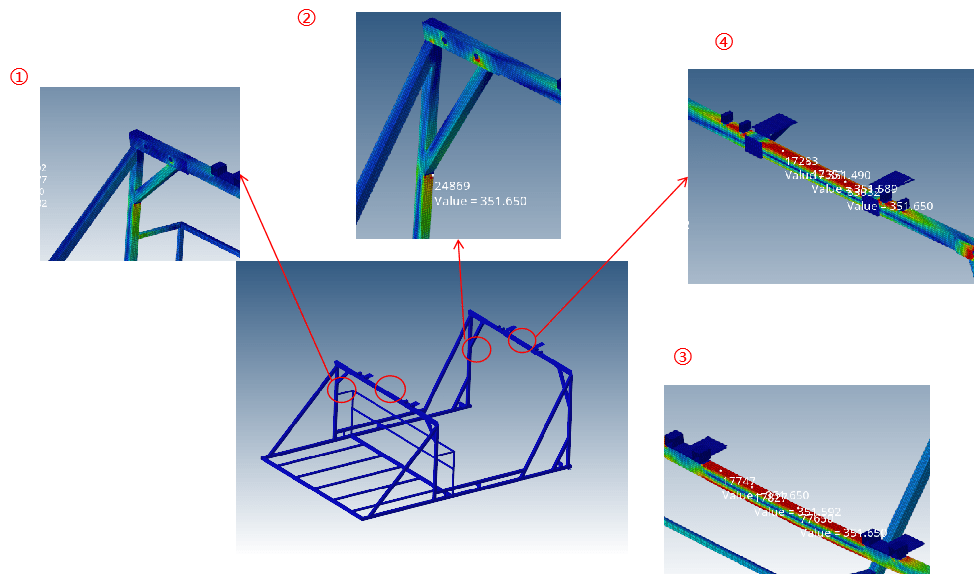

Packing Design and Verification

Strength Simulation

Maritime Shipping Simulation Test

Container Road-Shipping Test

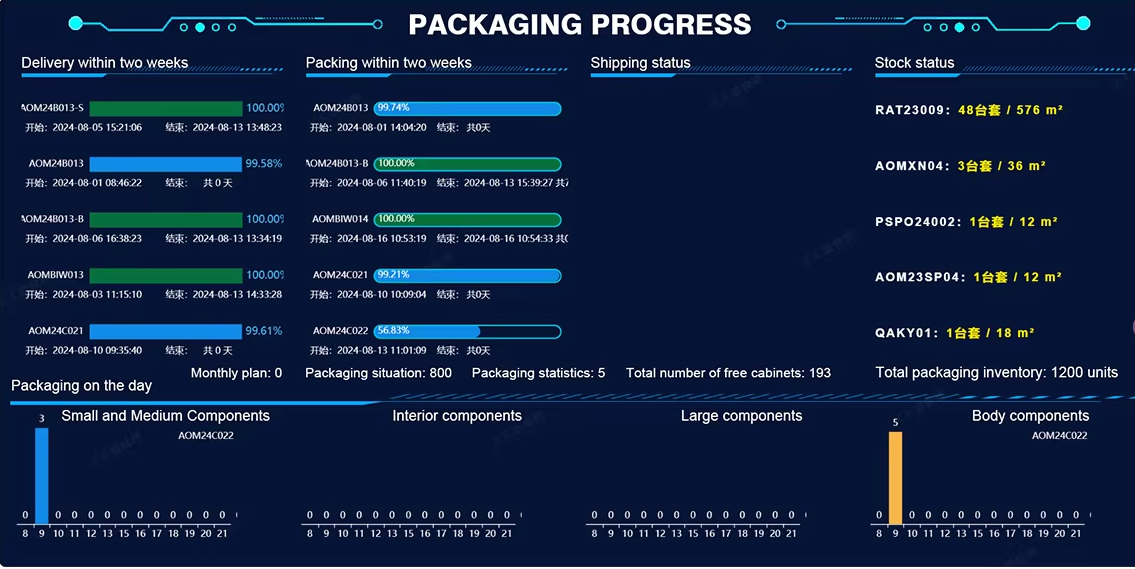

Digitization

Digital Data Collection and Management

Data Platform

Scan Code Storage System and QR Code Positioning

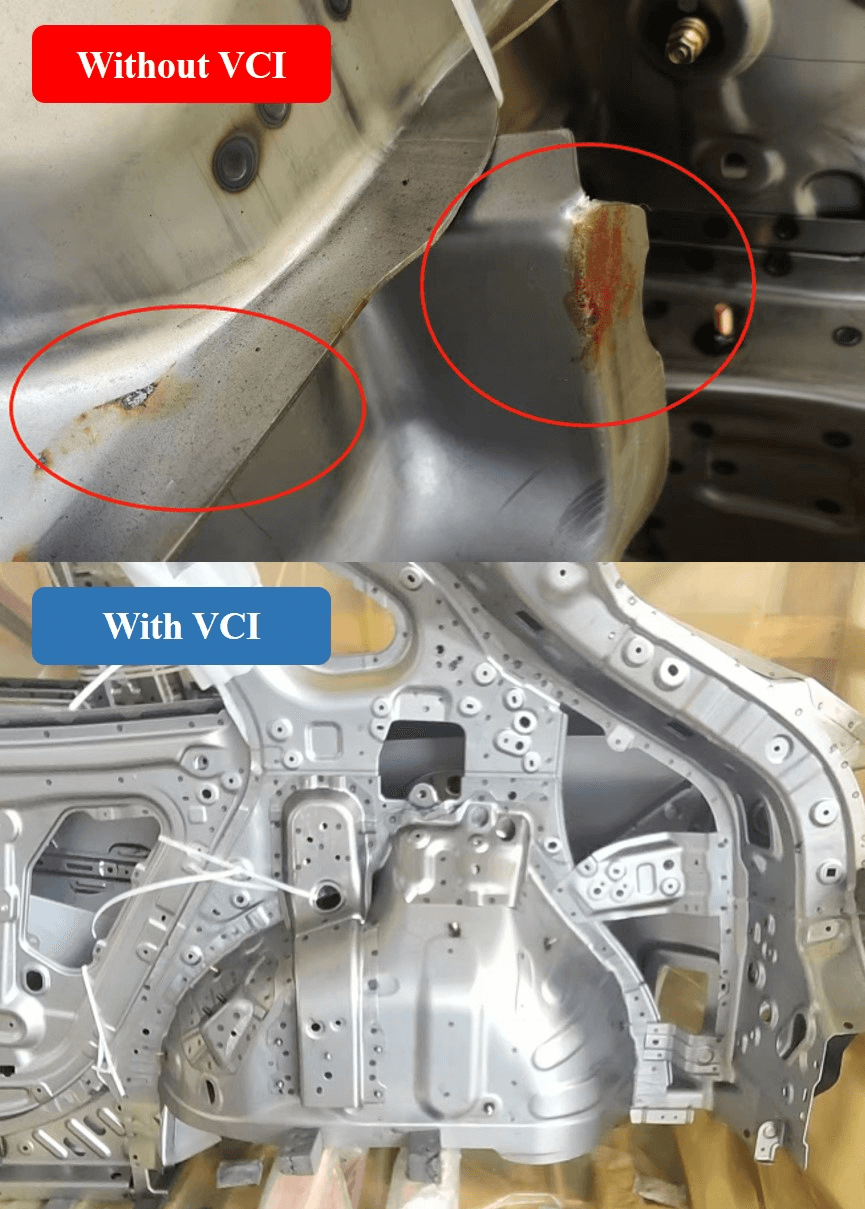

VCI(Volatile Corrosion Inhibitor)

VCI is superior to traditional methods, such as rust prevention oil, paint, and coating technology.

Parts Without VCI VS Parts With VC

External Packing

SUV

SUV

Mpv

Mpv

Sedan

Sedan

EV

EV